Dr Patrick Pradel

Senior Lecturer – Design and Creative Arts

Dr Patrick Pradel’s research interests lie in product design and development, digital fabrication (particularly Additive Manufacturing), novel technologies, and design education. His work explores the far-reaching impacts of digital manufacturing technologies on industrial design, including how they influence practice and education and how best to capitalise on emerging opportunities. He is currently the Principal Investigator for the AHRC-funded When Design Never Ends project, the EPSRC Network Design for Additive Manufacturing and a Royal Society Exchange Programme.

Exploiting Industry 4.0 technologies through Design

Additive Manufacturing (AM or 3D Printing) – the computer-controlled construction of a three-dimensional object from a CAD or digital 3D model – is a disruptive technology that offers a range of exciting design and manufacturing possibilities. Despite its many unique advantages, AM currently has several limitations. Patrick’s work addresses these drawbacks to help fully realise AM’s potential.

Design enables the radical and disruptive opportunities of digital manufacturing technologies. This provides many benefits – including added user value, increased product performance, improved productivity and efficiency, and greater possibilities for innovation and collaboration.

My work explores the impact of digital technologies – such as generative design, Topology Optimisation, Additive Manufacturing, and Laser Cutting – on industrial product design.

As well as revolutionising design and manufacturing processes, these technologies have exciting applications in fields such as consumer products, electronics, medical devices, water pumps, technical equipment, musical instruments and sports equipment.

For example, Additive Manufacturing enables the creation of bespoke parts with complex geometries. Design alterations can be made efficiently throughout the manufacturing process to develop both prototypes and final products.

In addition, objects that may previously have comprised several components can be one unit, increasing their performance and durability. Another exciting feature of the technology is the ability to create bespoke items more cost-effectively.

Despite these unique advantages, Additive Manufacturing has also many limitations. For instance, materials’ properties are not always comparable to those of bulk materials. Parts require further finishing processes such as cleaning and dyeing, and component cost is markedly influenced by size.

Taking into consideration both the capabilities and limitations is essential to effectively design valuable components and products made by AM.

Having witnessed the universal influence of AM, I’m really happy that my role as the lead of the EPSRC Network Design for Additive Manufacturing, provides academic and industry specialists the chance to connect so that we can pool our expertise and advance the widespread development and applications of AM technologies across all sectors.

To ensure that the next generation of designers can fully utilise and realise the potential of DfAM, it’s imperative that their training equips them with the skills and knowledge they need.

Alongside the Network, I’m also leading the AHRC-funded project When Design Never Ends.

The Co-Investigator, Professor Richard Bibb, and I aim to provide a conceptual framework for understanding the impact of AM in product design practice.

As part of this, we’re creating a systematic methodology for studying the evolution of design practice as well as a comparative analysis of design practices across different domains and sectors.

Our results will be shared via a virtual exhibition to inform professional designers and academic researchers about the evolution of industrial product design practice. We hope that the exhibition will encourage this much-needed shift in ethos and approach.

My research into Design for AM (DfAM) education and training has shown that this is crucial. The results of a co-created and managed online survey about the uptake of DfAM in higher education revealed that DfAM is taught across many courses, but its unique capabilities are not yet fully understood or exploited.

Although AM is an established discipline in both research and education, to achieve its full potential a step-change in design thinking is needed.

To ensure that the next generation of designers can fully utilise and realise the potential of DfAM, it’s imperative that their training equips them with the skills and knowledge they need.

My research journey

My journey in design research began at the Politecnico di Milano during my postgraduate studies.

I studied the relationship between design and digital fabrication with a thesis on the “Application of high brilliance laser sources to stainless steel machining”.

After my Masters, I had the opportunity to work as a Product Designer with Whirlpool’s R&D Department. This experience provided me with ample industrial experience including an insight into how R&D works in a big multinational company.

However, my passion for research brought me back to academia. In 2009, I won a scholarship and began my PhD studies in Design at the SITEC Lab. My research – fully funded by the BLM Group – explored the capabilities of tubular laser cutting in product design.

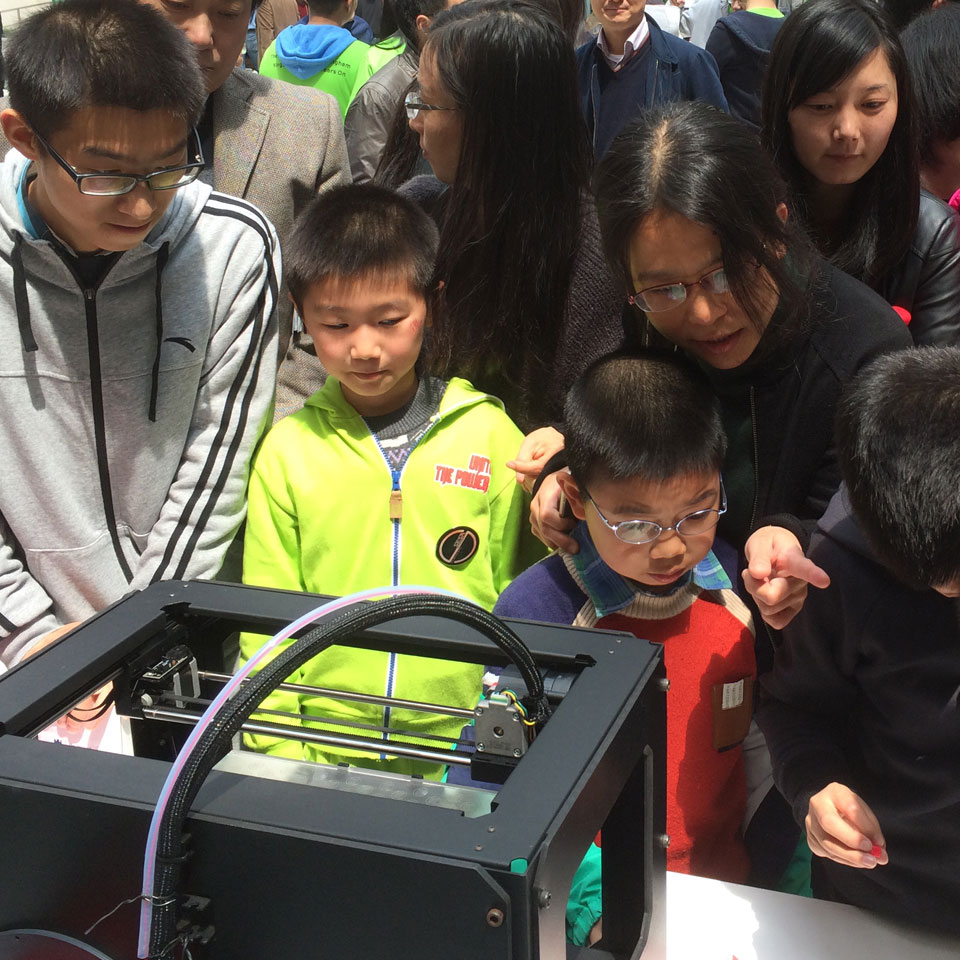

After my PhD, I took the exciting step of moving to China as an Assistant Professor at The University of Nottingham Ningbo. I worked there for about four years, contributing to the development of a brand-new programme in product design and manufacturing.

I also taught modules in design for manufacture, manufacturing process capabilities, automation, design process and product development and was my department’s exchange coordinator.

Being in China was an exciting experience. On a personal level, I was fascinated by being immersed in a completely different culture.And, on a professional level, I was gratified by my first academic appointment which entailed responsibilities and career development.

In January 2016, I came to the UK – joining Loughborough as a Research Associate with the ESPRC-funded project Design for Additive Manufacturing (D4AM) in collaboration with the University of Cambridge. Albeit my experience in China was rewarding, I felt the need to step up my game and grow my research expertise.

Then, as part of the H2020 project AMaTUC, I explored the competitive manufacturing of personalised products and computer planning (CAEFEM) analysis and simulation and developed a framework of the variables that affect product personalisation.

In 2017, I secured the role of Lecturer in Product Industrial User-Centred Design, and was promoted to Senior Lecturer in 2022.

Alongside my research and teaching, I’m a topic editor and reviewer for several academic journals; and, for the past 15 years, have provided design consultancy support – around AM and laser cutting – to several companies across Europe – such as Valcucine, Grundfos, BLM Adige.

I see my future research endeavours supporting the exciting evolution of industrial design practice by looking at the intersection of design practice, digital design tools and advanced manufacturing technologies.