Dr Mey Goh

Reader in Transdisciplinary Digital Manufacturing – Mechanical, Electrical and Manufacturing Engineering

Dr Mey Goh’s research explores transdisciplinary approaches to the design of inclusive and sustainable industrial systems, by extending the boundaries of engineering to solve complex problems. She is particularly interested in the role of people within future digitalised manufacturing systems, and how to support widespread adoption and use of industrial digital technologies. She has grown a strong network of research partners – both academic and industrial – with whom she has successfully secured more than £10 million funding for a variety of projects.

Ensuring the human-centred transition to digitalised manufacturing systems

Industrial digitalisation is transforming how we live and work. It impacts every sector imaginable – spanning construction, utilities, healthcare and manufacturing. Mey is investigating how digital technologies can be designed and used – ensuring that the transition to future digitalised manufacturing systems is inclusive and sustainable.

I work within transdisciplinary engineering which is increasingly recognised as a necessary holistic approach to overcoming the complex engineering challenges we currently face. In my research, I regularly adopt methodologies from a range of subjects to underpin novel modelling and data-driven ways to generate new knowledge and insights.

My vision aligns with the emerging concept of Industry 5.0 – emphasising a human-centric approach that places worker wellbeing at the heart of the manufacturing process. In other words, Industry 5.0 requires a shift from a focus on economic value to a focus on societal value, and from welfare to wellbeing.

Over the years, I’ve built up expertise in uncertainty analysis, machine learning, informatics and knowledge management – and applying these to intelligent automation, design engineering and industrial servitisation.

I’ve been involved in some exciting and ground-breaking projects with colleagues across the University as well as with academics from around the world and industrial partners in a variety of sectors. Together, we’ve investigated some of the exciting, fuzzy areas of innovation on the boundaries between engineering, management, computer science and human factors.

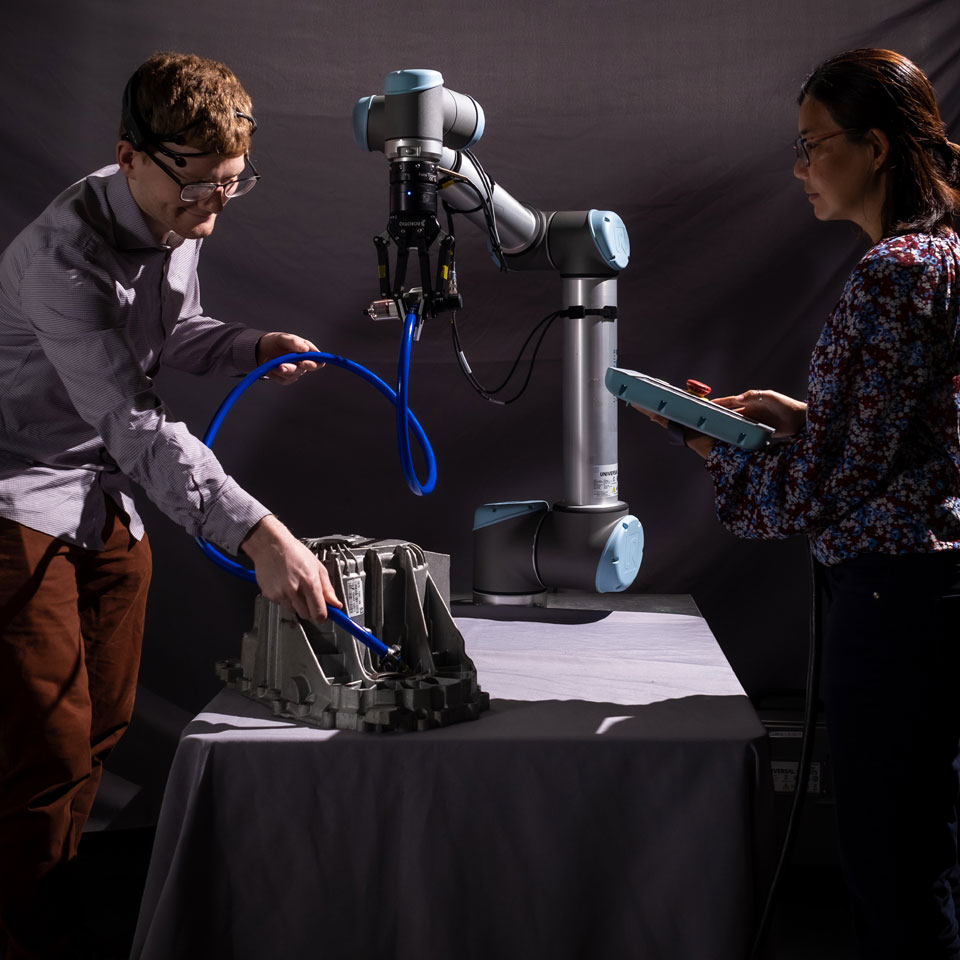

For example, we’ve looked at user-centric, explainable AI and how to augment machine learning models with expert knowledge in high-value, low-volume manufacturing. We’ve also explored data-driven human-robot interaction models, business cases for intelligent automation as well as mental health and trust in automated systems.

It’s so rewarding to see my work make a difference – positively impacting industry knowledge and practice.

I am currently a Co-Investigator of the Made Smarter Innovation: Centre on People-Led Digitalisation, working with colleagues at Bath and Nottingham universities as well as several UK industry partners to realise the potential of a people-led approach to digitalisation.

Our main driver is to accelerate the UK manufacturing industry’s adoption of digital technologies that will complement their workers’ expertise and skills – helping them to innovate and thrive.

It’s always been important to me that my research addresses real-world challenges which is why I collaborate with so many industry partners and policy makers. It’s so rewarding to see my work make a difference – positively impacting industry knowledge and practice.

My research journey

I’ve always been good at Maths and Science – so, studying a STEM subject was an obvious choice for me. At A-level, I initially wanted to study Chemical Engineering, but was drawn to Mechanics and found that it came naturally. So, I guess you could say it was more a case of Mechanical Engineering choosing me – rather than vice versa.

I was an undergraduate student at home in Malaysia where I completed my BEng (Hons) in Mechanical Engineering at the University Tenaga Nasional in 2001.

When I graduated, I was thrilled to secure a prestigious UK Overseas Research Students Award to pursue my PhD in Mechanical Engineering at the University of Bristol. My thesis explored knowledge management strategies to support the use of probabilistic design to better model the uncertainty affecting product performance.

When I finished my PhD, in 2005, I moved to the University of Bath to join the Innovative Design Manufacturing Research Centre and the EPSRC-funded Grand Challenge IITKM project. My research focused on through-life Knowledge and Information Management (KIM), and uncertainties in through-life costing and bidding for product-service systems.

This work really fostered my interest in the design and engineering of complex socio-technical systems. Working at the interface between engineering and a range of other disciplines – including management and computer science – I became fascinated by the essential role of people in all kinds of engineering systems and processes.

I am always curious to learn new things and like to push the envelope for engineering research and teaching. Doing research satisfies my natural curiosity, but I am a design engineer at heart. I see my work as a mediator – developing ways to deliver and integrate new knowledge and understanding of user requirements to optimise technological systems – thereby, increasing the acceptability and success of new approaches.

I joined Loughborough in 2010 where I am a Reader in Transdisciplinary Digital Manufacturing.

Soon after joining the University, I became a Co-Investigator in the EPSRC Centre for Innovative Manufacturing in Intelligent Automation (now, the Intelligent Automation Centre). I’m proud to say that, alongside our research, I have successfully supported 15 PhD students.

I’m especially keen on developing international collaborations and supporting exchanges for my students. The opportunities I’ve had have broadened my horizons and perspectives enormously. I want to give my students similar opportunities because knowledge has no boundary – only by working together we can truly push the frontier of knowledge.

The future is uncertain, but exciting. My hope is to be able to play a part in contributing to the rapidly changing engineering landscape, both in research and education.

I’m passionate about equipping students with the knowledge and skills to be able to “speak the language of multiple disciplines”. By fostering their problem-solving and technical abilities – while nurturing their teamwork, communication and creativity skills – I hope that I’m helping them to grow as successful future engineers.