X-ray Computed Tomography

X-ray computed tomography (CT) is a non-destructive 3D imaging technique used to visualise internal structures of specimens ranging from particles suspended in organic matter to cracks within metallic structures. It's ability to image components down to a few microns in resolution makes it a great addition to the equipment housed in LMCC.

The facility enhances the understanding of products on a large scale, with the integration of focused ion beam (FIB) tomography we can achieve imaging with resolution down to the nanoscale, enabling measurements that span from millimeters to nanometers.

X-ray CT scan uses

- Non-destructive testing

- Detection of crack, porosity, voids, and inclusions

- Measuring complex internal & external geometries

- Reverse engineering

Example applications

- Automotive/aerospace component analysis

- Additively manufactured print defects

- Carbon fibre orientation modelling

- Porosity measurements in concrete

- Cross-sectional analysis of integrated circuit boards

- Delamination in multi-layer paint

- Validation of 3D printed parts internal lattice structure

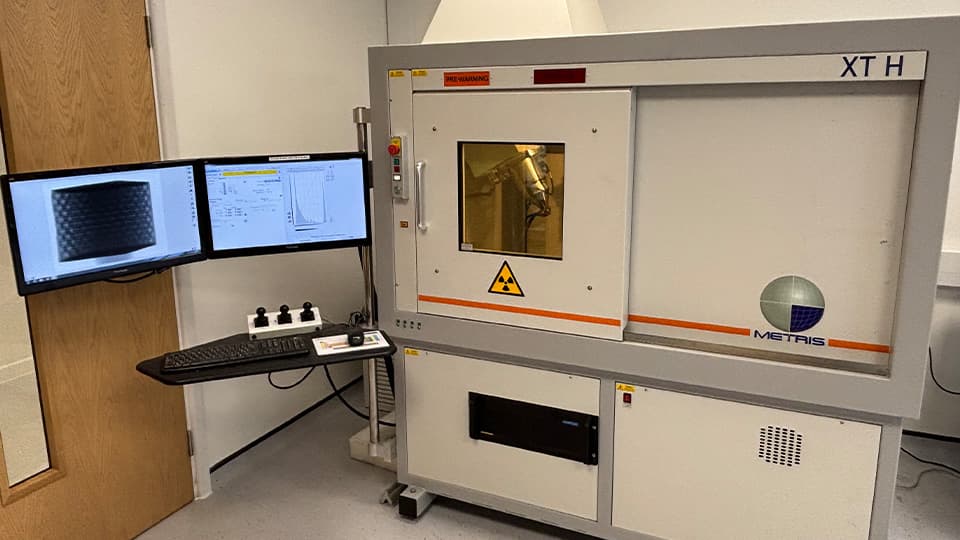

Nikon XT H 160i

- Liquid cooled X-ray voltage 50-160 kV

- Transmission detector

- Window 1920x1536

- Voxel size ranging between ~5-100µm

Sample Size

- Typically a few centimeters

- MAX 180mm diameter, 300mm height, 10kg

Are you interested in using this technique?

If you are interested in using this technique and would like further information please do not hesitate to get in touch.