Dilatometry

Dilatometry is a method for characterising the dimensional changes of materials with variation of temperature conditions. Measurements can be taken over a range of temperatures, or a pre-programmed cycle of temperatures to mimic an industrial process. Investigations that typically use a dilatometer include; coefficient of thermal expansion, annealing studies, glass transition point, softening point, densification, kinetics and sintering studies.

BÄHR Thermoanalyse GmbH

MODEL DIL-805

Description

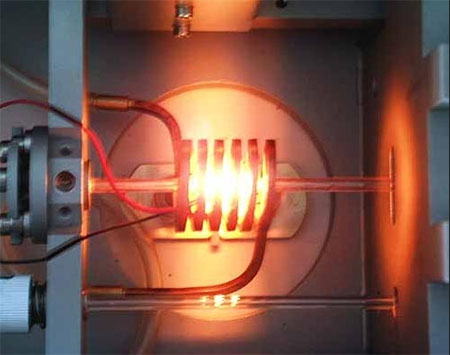

Horizontally operating quenching and deformation dilatometer, for the measurement of thermal change in the length of a body as a function of temperature - dilatometry. Can be operated at normal atmosphere, in a vacuum or inert gas.

The dilatometer can be operated in a quenching mode providing cooling rates of 2500K s-1, the system can also be operated in a deformation mode, which can provide deformation rates from 0.01 up to 125 mm s-1. The system allows the change in length of a body as a function of temperature to be measured with a resolution of 50 nm. The system can be used to in the creation of TTT and CCT diagrams.

Specification

- Length changing: 7mm

- Resolution: 50nm

- Sample length max: 50mm

- Sample diameter max: 5mm

- min. temperature: 20°C

- max. temperature: 2400°C

- Deformation force max. 25kN

Are you interested in using this technique?

If you are interested in using this technique and would like further information please do not hesitate to get in touch.