SEM detectors for particle analysis

What we did

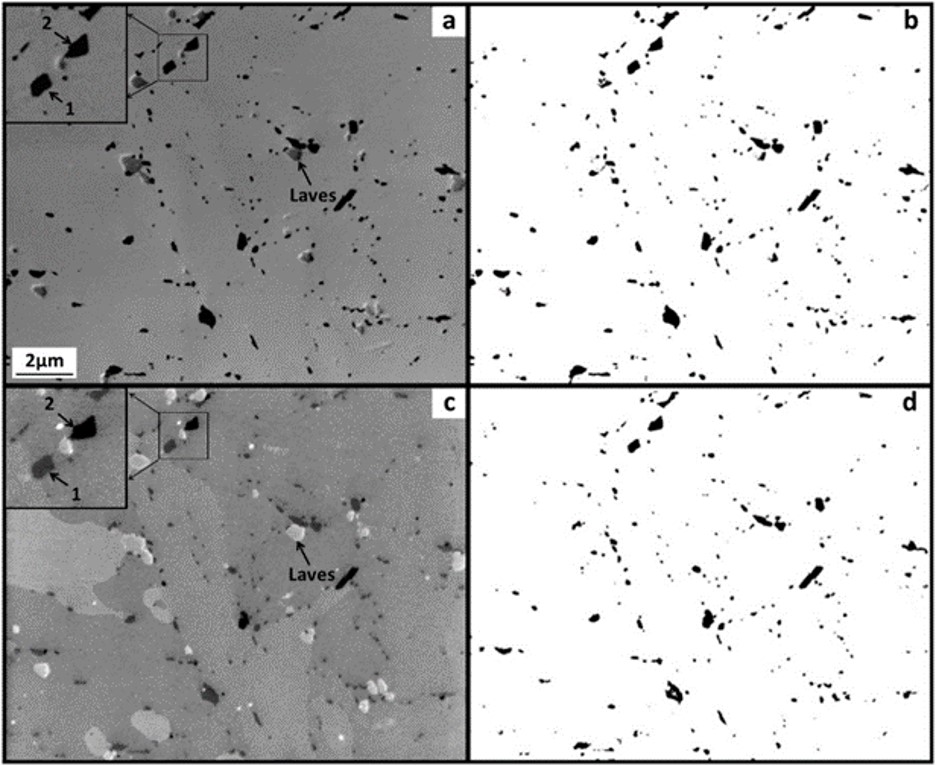

In this work, we characterised 12wt.% Cr steels using LMCC-based electron microscopy techniques to determine the phases present and their area fraction. To reveal the phases present, we first used the more conventional imaging process of ion induced secondary electron (ISE) imaging to determine the distribution of carbides in the microstructure (Fig1a). We found however, that some of these particles were chemically distinct so a different approach was required. For this, we used the Upper Secondary Detector (USD) in our Jeol 7800F to produce images which showed varying contrast between correlative areas (Fig1c) allowing a comparison between ISE and USD imaging. Fig. 1. Images from thermally aged steel taken with: a) FEI Nova Nanolab 600 DualBeam FIB-SEM with XeF2 IEE; c) JEOL 7800F FESEM USD; b, d) mask image of analysed particles from FIB and FESEM USD images, respectively. Magnified images (top left-hand corner) in a and c highlight different greyscale intensities of two potentially different particle types, termed type 1 and 2.

Fig. 1. Images from thermally aged steel taken with: a) FEI Nova Nanolab 600 DualBeam FIB-SEM with XeF2 IEE; c) JEOL 7800F FESEM USD; b, d) mask image of analysed particles from FIB and FESEM USD images, respectively. Magnified images (top left-hand corner) in a and c highlight different greyscale intensities of two potentially different particle types, termed type 1 and 2.

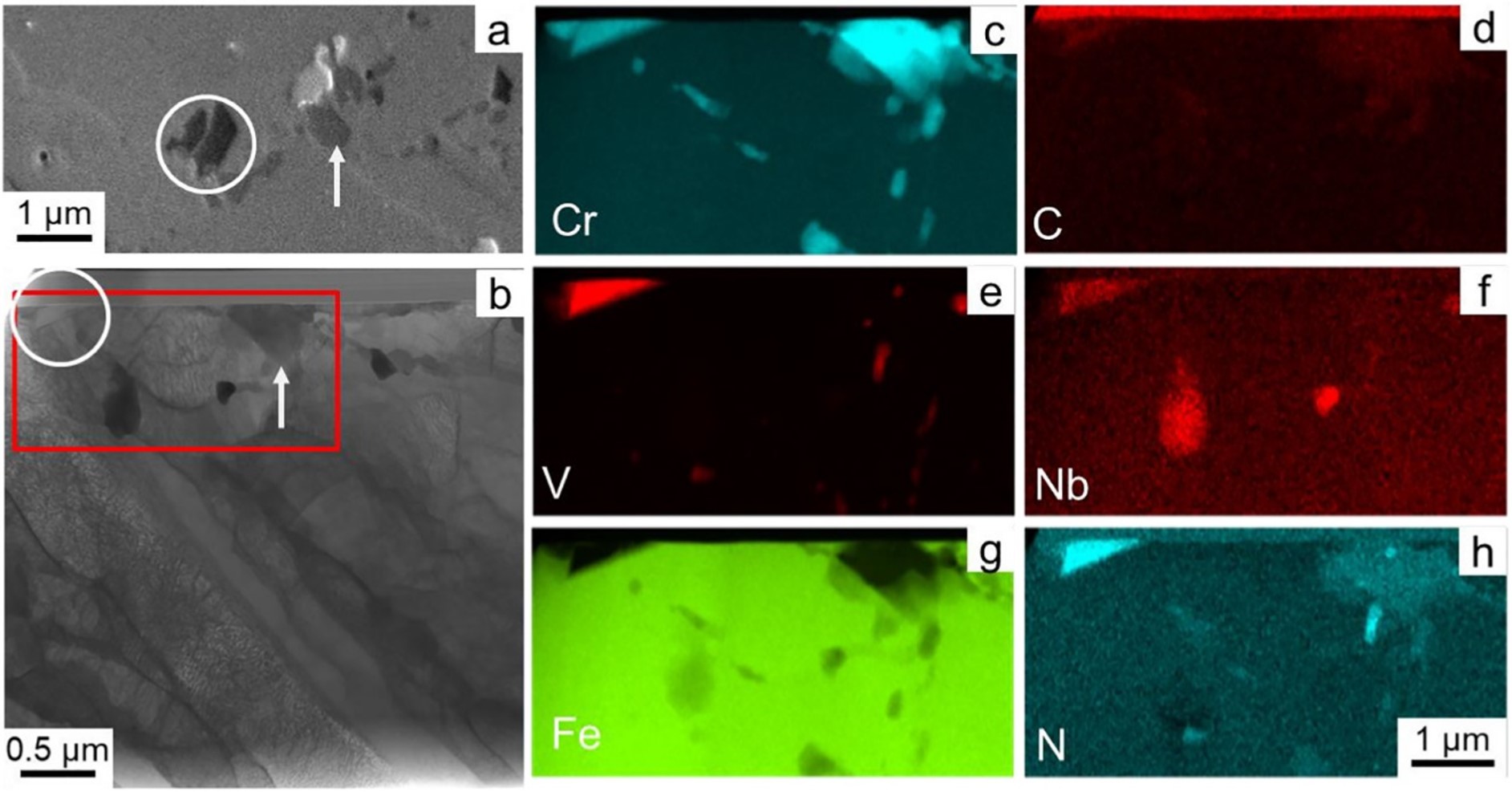

LMCC’s expertise was used here to develop suitable preparation of the surface to allow correlative ISE and USD imaging of the same area and to provide transmission electron microscope (TEM) analysis of the particles (Fig 2), following a site-specific TEM sample extraction using focused ion beam (FIB). Fig. 2. a) a JEOL 7800F FESEM USD image of an area containing a type 1 particle (arrow) and a darker type 2 particle (circle); b) a BF TEM image of a corresponding TEM lamella containing the particles of interest; and c-h) EDS analysis of the lamella.

Fig. 2. a) a JEOL 7800F FESEM USD image of an area containing a type 1 particle (arrow) and a darker type 2 particle (circle); b) a BF TEM image of a corresponding TEM lamella containing the particles of interest; and c-h) EDS analysis of the lamella.

What we found

We found that although the ISE images do give a good overall picture of the content of carbides in the structure, some of these particles may be additional phases. In this case, the particles of differing contrast in the USD image were in-fact Z-phase particles which was confirm by futher analysis in LMCC's TEM (see published paper for more details).

Why is this important?

This is important because the growth of different phases within the steels may have a different effect on their properties. Tracking and characterisation of changes over time at high temperature will provide us with a greater understanding of the chemical composition and the heat treatments required for long term operation of high temperature plant.

Summary

LMCC instruments give a range of analysis options for these particles which have different advantages and disadvantages.

Publications / References

This work is published as a journal article here: (Detection and quantification of precipitates in 11–12 wt% Cr steels using in-column secondary electron detectors - ScienceDirect) and as part of the theses of Dr Robert Byrne available here: Understanding the performance of 11–12 wt. % Cr creep strength enhanced ferritic steels, through microstructural characterisation and investigation of precipitate quantification techniques (lboro.ac.uk) and Dr James McGladdery here: Secondary electron energy filtration: methods and applications (lboro.ac.uk)