Additive manufacturing

Loughborough University specialises in interdisciplinary research in additive manufacturing and 3D Printing addressing applications in art, design, heritage, engineering, sciences and healthcare.

Our unique approach to additive manufacturing research combines academics from a wide range of disciplines to tackle a variety of challenges in areas such as design for additive manufacturing, innovative printing control software, multi-functional 3D metamaterials, directional composites, customisation and personalisation, archaeology, sculpture, heritage, prosthetics and orthotics, body armour, scientific equipment, printed electronics, architecture and construction.

Our multi-disciplinary research, coordinated through the Additive Manufacturing Network, has delivered novel processes, invented at Loughborough, with the potential to deliver widespread economic and societal impact.

3D concrete printing

Employing a digital manufacturing approach, our research on 3D Concrete Printing (3DCP), a technology invented at Loughborough, has shaped the international research landscape of large-scale additive manufacturing for construction. Our current research is focused on novel reinforcement techniques, material science and the development of robotics for material placement. We are achieving impact through our start-up company, Concrenetics.

FullControl GCode Designer

We developed open-source software which facilitates explicit design of print paths for additive manufacturing and enables unparallel levels of process control. We have used it to research fundamental process capabilities and material properties. It also allows entirely new types of geometry and structures to be designed that would be impossible with conventional additive manufacturing software and workflows. Another benefit is that FullControl allows designers to eliminate process-induced defects by designing out their root cause.

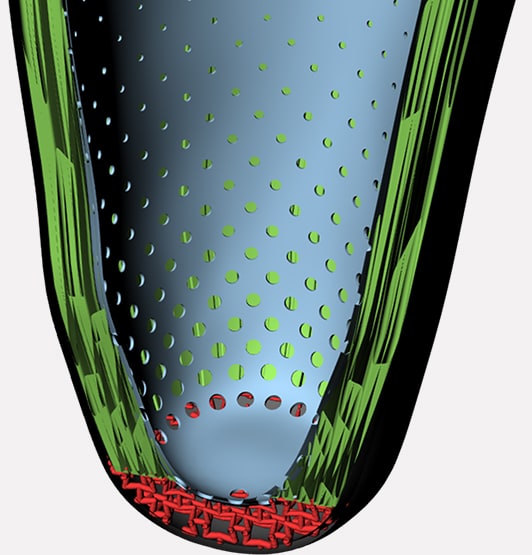

Personalised prosthetic sockets

We aim to increase the lifespan of children’s prosthetic sockets by using additive manufacturing to incorporate auxetic structures into a novel design. When stretched, auxetic structures become thicker perpendicular to the applied force. Their mechanical properties such as high energy absorption and fracture resistance could offer the potential for prosthetics with increased comfort and safety, as well as a robust and personalised prosthetic socket suitable for children’s exercise and play, and adaptable to limb growth.

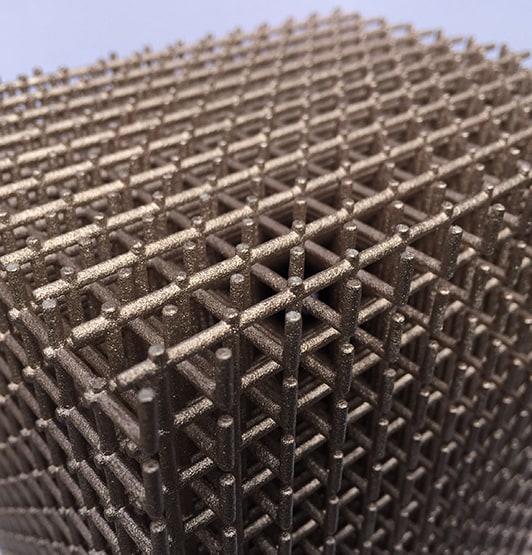

3D metamaterials for communication

We led SYMETA: Synthesizing 3D Metamaterials for RF, Microwave and THz Applications; to develop novel ultra-low loss ceramics that are temperature stable and can be 3D Printed to create graded structures with multiple materials. Introducing these novel structures into the complex world of electronic design offers a radical new way of designing and manufacturing electronics.

Directional Composites through Manufacturing Innovation

We lead the pan-European transdisciplinary project to develop a new method of producing composite material parts with optimised fibre directionality. Directional Composites through Manufacturing Innovation (DiCoMI) will have a direct impact on the European and international scientific state of the art in the fields of composite additive manufacturing, while supporting the innovation potential in the automotive and aerospace industries.

Cultural heritage conservation

Our research is helping the cultural heritage sector to maximise the benefit of emerging technologies – including 3D scanning and printing – combining them with traditional techniques to improve the preservation, curation, and replication of priceless historical and archaeological artefacts.

High Speed Sintering

High-Speed Sintering (HSS) - invented at and patented by Loughborough - is the first and, to date, only 3D-printing process to enable low-cost, high-volume, mass manufacture of complex and customisable parts, that competes economically with injection moulding. Many sectors have adopted HSS in their end-product supply chains - including aerospace, automotive, consumer goods, healthcare and medical - and a growing number of global brands have adopted HSS to create their products.