Robust Intelligent Metrology

Metrology plays a critical role in all high value manufacturing processes. There is an increasing demand for ever more data to control how complex products are manufactured, and ensure they consistently meet quality standards. Our aim is to provide more metrology solutions that can be deployed in a factory environment thereby reducing the reliance on specialist metrology facilities – reducing cost and measurement process time, and increasing the usefulness of the data.

Our aim

The Robust Intelligent Metrology Lab is focused on providing metrology systems that function as close to the manufacturing action as possible; this can be at the line side, in the cell, in the machine or even within the manufacturing process. We focus on three core activities:

- Creating and developing new robust sensor technology by designing sensors that are better able to cope with challenging industrial applications.

- Defining new ways to automate and enhance the use of existing sensors with greater intelligence, by providing tools and algorithms that assist in the selection, placement and configuration and optimization of sensors.

- Integrating sensor systems as part of collaborative metrology networks to provide more robust measurements, with greater coverage of the measurands, and increased confidence in the data.

Automation is at the heart of the technology we create, and it is a strong theme within all our metrology activity. We aim to embed intelligence within our technology that allows it to function robustly in an automatic way, allows the measurement to be configured with less human intervention, or enables other processes to run more autonomously in a robust and reliable way.

What are the outcomes/impacts so far?

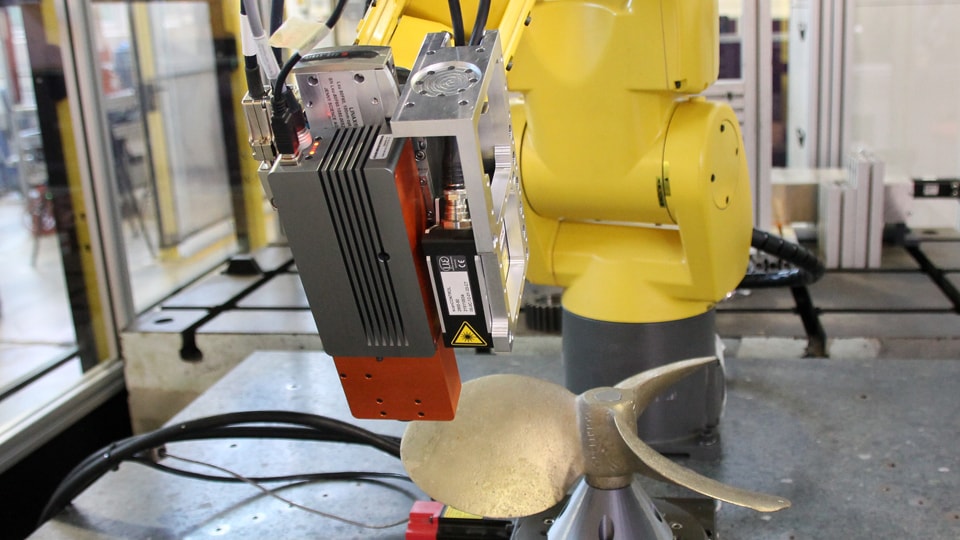

- A special purpose robot mountable low-cost 3D scanning system.

- A large volume metrology system for marker-free motion capture of people in crowded scenes.

- A new 3D sensor characterisation method with a special purpose test rig for automated sensor evaluation.

- A 3D vision simulation approach that can be used for off-line measurement planning and optimisation.

- New data driven strategies for defect detection using robot mounted laser scanners.

- A lens-free high precision fibre-based sensor for in-process metrology.

- A multi-sensor, robot integrated, surface inspection system.