Facilities

Our well-resourced lab provides our researchers with a wide range of industrial scale equipment ideal for developing new proof of concept demonstrations.

As part of the Wolfson School of Mechanical, Electrical and Manufacturing Engineering at Loughborough University, the Intelligent Automation Centre has recently moved to a brand new purpose-built lab in the heart of campus. Our facility is used for industrial research into robotics and connected systems, where our research focuses on productivity, agility, efficiency and resilience.

The Intelligent Automation Centre has collaborated on a variety of research projects with industry leaders including Rolls Royce, Airbus, Network Rail, Ford and Toyota and we also work closely with research catapults such as The Manufacturing Technology Centre (MTC).

Our facility houses a range of industrial robot cells associated with core research groups:

- Robots from a range of manufactures, including ABB, FANUC, KUKA, Universal Robots and Yaskawa

- A dedicated digitisation space designed for flexible experiments into human-robot collaboration

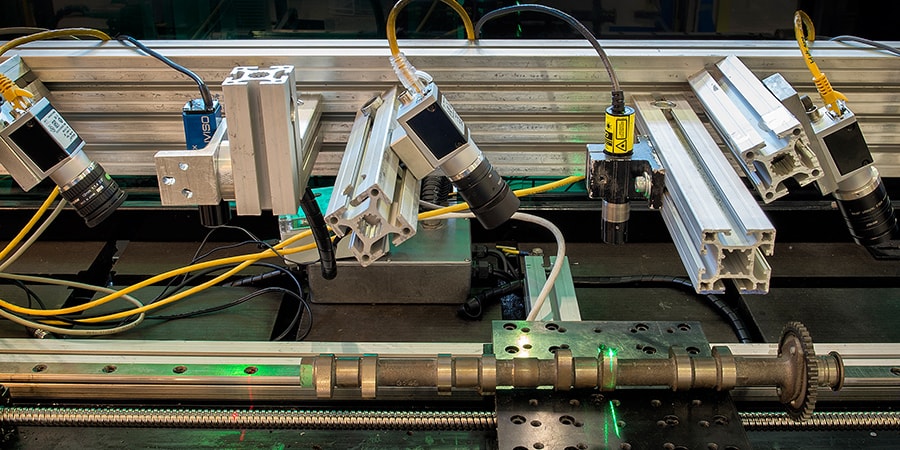

- A combination of sensors which allows for extensive data capture, ranging from high-frequency Vicon motion tracking to Nikon K-CMM optical trackers for millimetre accuracy during room-scale movements

- An in-house developed machine learning algorithm for human tracking using visual cameras which can track and determine the current status of multiple interacting humans in real-time

- Equipment for automated welding in which we have extensive experience, including human skill capture and adaptive TIG welding

- 3D sensor characterisation and advanced robotic 3D scanning

- Demonstrator cell of mobile robots and static industrial robot arms

- Hybrid manufacturing setup for additive (welding) and subtractive manufacturing

- Soft and flexible gripper testing and manufacturing facilities, including electroadhesion

- 3D printing and other rapid prototyping facilities for building custom mechatronic solutions including 6 Prusa MK3 i3’s and PCB prototyping

Our current research topics include:

- Industry 4.0 and the digitisation of manufacturing

- Computer vision for perception and safety

- Machine-learning and agent based process optimisation

- Responsive manufacturing

- Human-robot collaboration

- Research into physical and physiological sensors (including EEGs) allows for predictive human motion estimation prior to any actual movement

- Automated assembly of complex materials including flexible pipe layout within confined spaces

- Robot Programming from Demonstrations (PfD)/Learning by Demonstrations (LfD)

- Robotic welding and hybrid manufacturing

- Soft and flexible robotic part handling

We work closely with both the Civil Engineering and the Aeronautical and Automotive Engineering departments within Loughborough University and are currently undertaking a number of collaborative research projects with them.