Solution-grown thin film solar cells

Developing thin film solar cells using a cheap, non-toxic and atmospheric deposition process has the potential to rapidly accelerate the roll out of low-cost electricity generation to a wide population.

Our Aim

Reducing carbon emissions whilst creating a sustainable energy economy is one of the key challenges facing us today, with low cost generation of electricity using photovoltaics identified as being a key player to address this important issue.

With this in mind, our fundamental aim is to develop photovoltaic technologies which can ultimately produce electricity at low cost, in a green and sustainable way. Photovoltaics based on thin film Cu(In,Ga)Se2 (CIGS), CdTe and CuzZnSnSe4 (CZTS) all have the potential to reduce the cost of electricity generated from photovoltaics compared to commonly used silicon solar cells. They offer the promise of lower manufacturing costs since their thicknesses are a fraction of those used in silicon photovoltaics (2μm compared to 150μm in silicon); they can be grown on flexible and lightweight substrates and can be easily integrated into buildings.

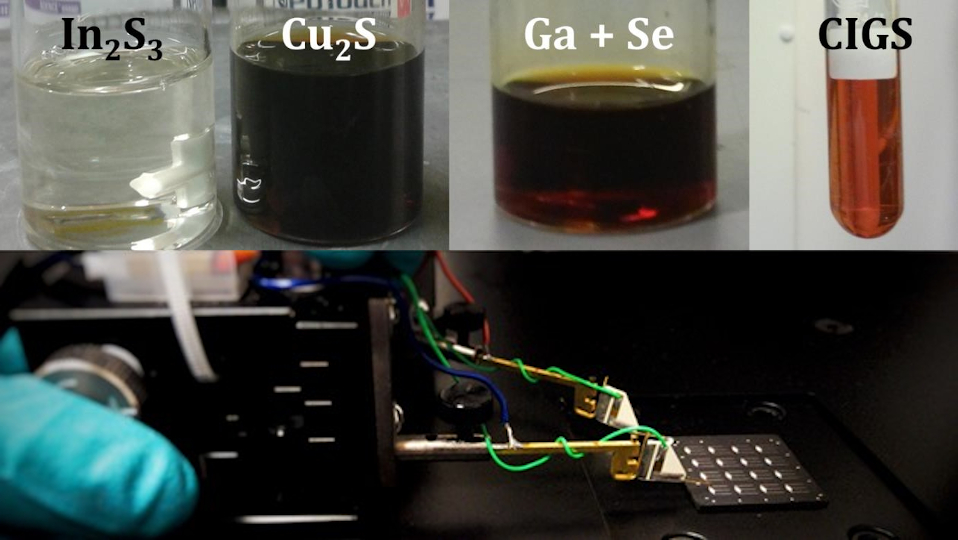

Growing thin film solar cells using low cost solution processes offers further cost savings which can be passed on to the end user. Our work primarily uses novel solvent combinations and metal chalcogenide precursors (compounds containing sulphur, selenium or tellurium) to fabricate thin film CIGS, CZTS and CdTe solar cells with low impurity content leading to high power conversion efficiency, whilst using low cost manufacturing processes which are industrially relevant and easily scalable.

Our Research

Research at CREST is focussed on the development and optimisation of an in-house developed process involving spray-pyrolysis of mixed elemental and binary selenide precursor solutions. The current best performance for solution CIGS is achieved using a hydrazine solvent, which is both toxic and highly explosive. The process developed at CREST uses much milder solvents which are easy to handle and can be incorporated into industrial manufacturing methods. Solar cells produced using this process have already reached efficiencies in excess of 12%, and ongoing work is leading to significant improvements. Additional advantages of this process include simple addition of beneficial dopants, as well as close control of the film composition through alterations to the precursor concentrations in the starting solution. Research in this area is carried out in collaboration with a number of colleagues at other universities including Bath University, Bristol University and Northumbria University.

Our Outcomes

This work has resulted in rapid efficiency gains for a non-toxic, stable and safe solution deposition process for CIGS devices, with current best performance in excess of 12%. The process itself is much safer and therefore more industrially appropriate than the current standard solution-based process for these devices.

The energy we get from the sun is vast. More energy, in the form of sunlight, hits in the earth in one hour than the whole world uses in one year. It is important that we tap this huge energy source effectively, and thin film solar cells grown using low cost manufacturing processes can do this, allowing a wide population to access cheap electricity.