A centre of excellence for materials characterisation and analytical services

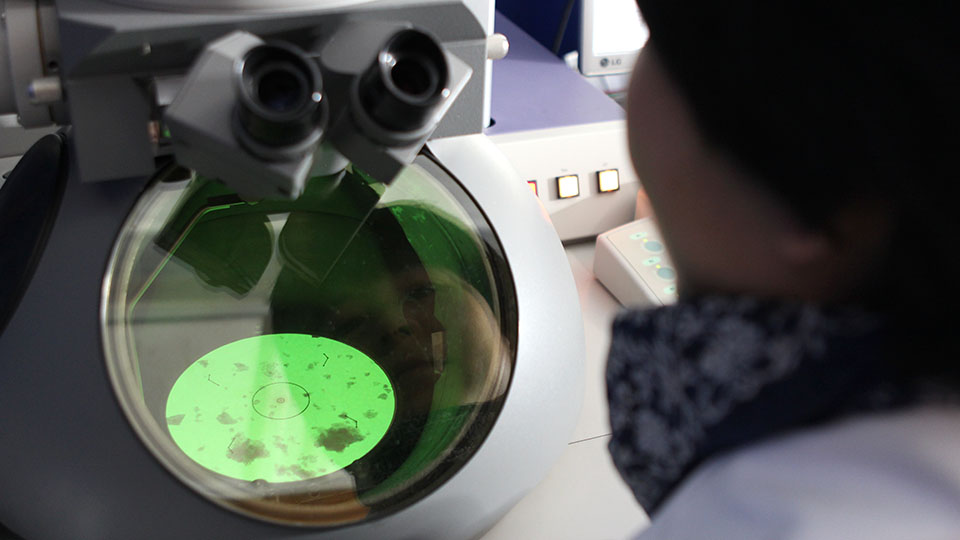

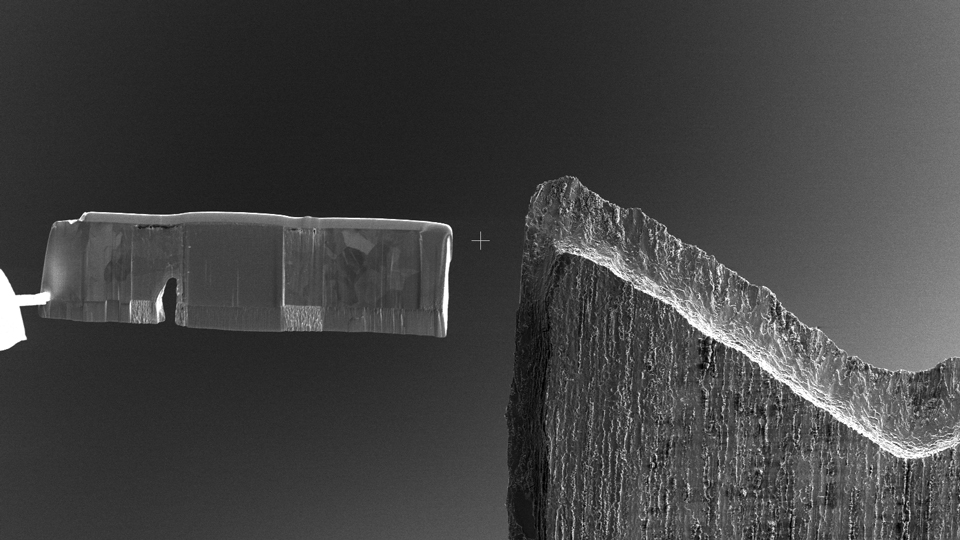

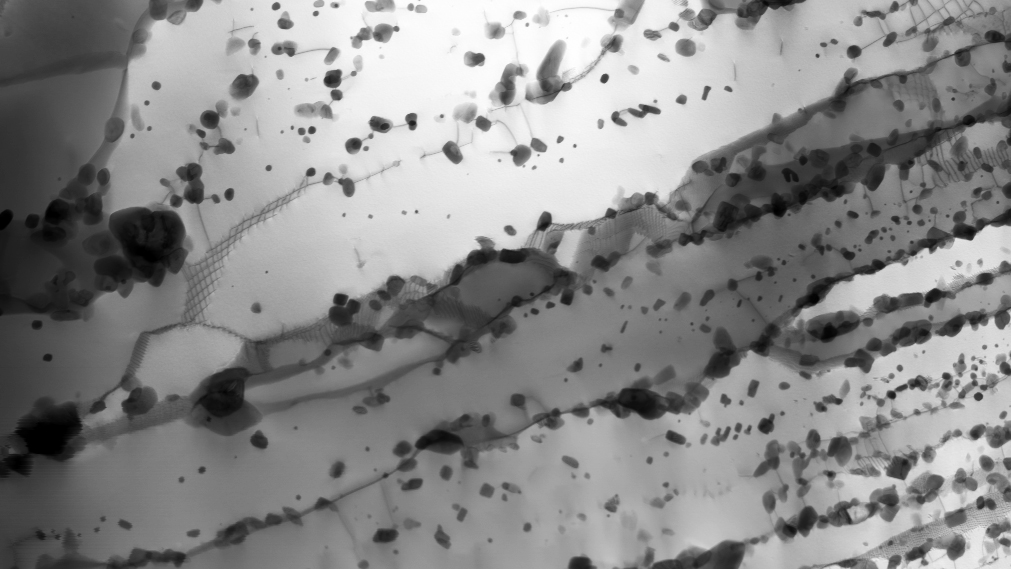

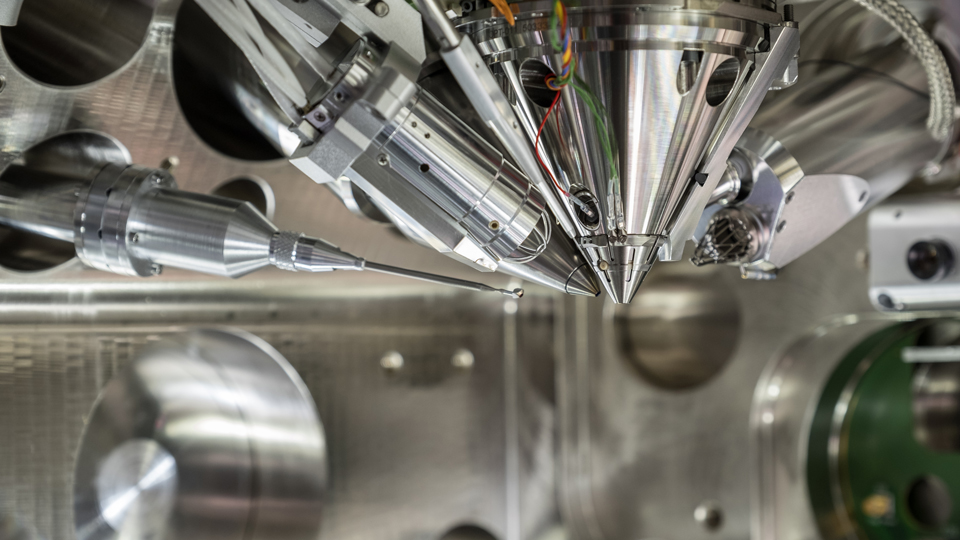

LMCC combines the talents of an experienced team of researchers and technicians together with world-class equipment, to offer a unique service to users, both academic and industrial.

Our Flexible Services for Industry

Services for the Global Research Community

LMCC is a core research facility at Loughborough University. We can support all researchers at the university who require advanced materials characterisation. We also actively engage with researchers from other institutions to develop collaborative research links.