Technology

LRU and maintainability

Conventional points operating equipment is maintained and repaired lineside. This exposes maintainers to the risks associated with working trackside, and requires the maintainer to stop the passage of trains for this time.

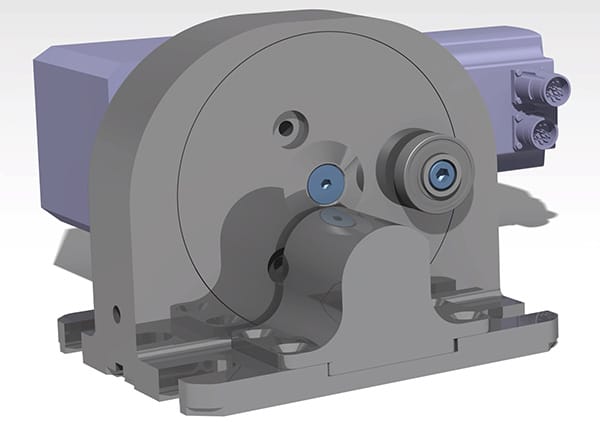

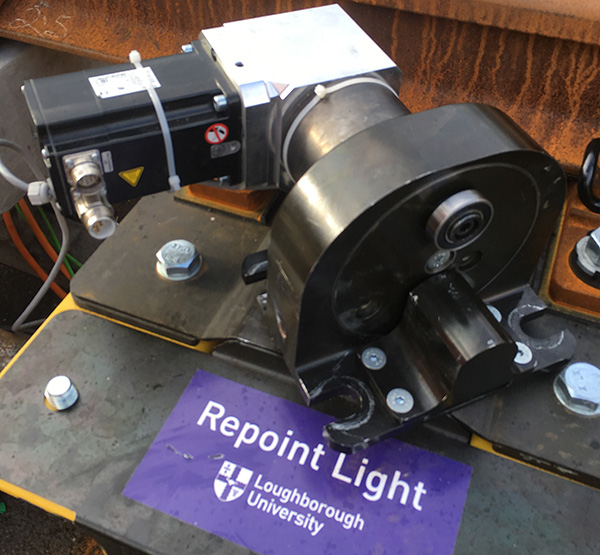

The Repoint motor/cam/gearbox assembly is designed as a line replaceable unit (LRU). These can be removed and replaced with a minimum of adjustment. Repairs will not need to be done trackside.

The LRU’s also include a large bearing. This replaces the lubricated slide chairs on traditional designs. As the rails are lifted during the motion, there is no longer any contact with the slide chairs. The bearing is sealed from dust ingress and is maintenance-free for the life of the gearbox unit.

All repair and servicing operations can be undertaken off track, away from the time pressures of the operating railway. Maintenance can be carried out safely in a workshop environment, rather than working trackside in the dark or rain.