Research and innovation

Our multidisciplinary research addresses the current and future challenges for our society through engineering solutions.

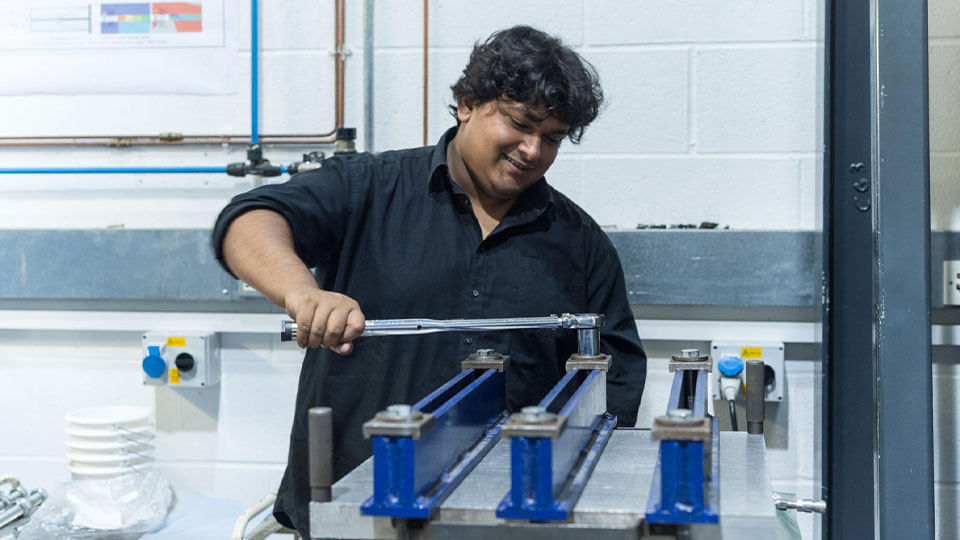

Our researchers in the Department of Aeronautical and Automotive Engineering are transforming the future of transportation and aviation. Their work is addressing some of the world's most pressing challenges, such as reducing carbon emissions, developing sustainable technologies, and enhancing vehicle safety and efficiency.

Through cutting-edge research and strong collaborations with industry and academic partners, we are driving innovation that has the potential to revolutionise the aviation and automotive industries. By translating our research into practical solutions, we aim to contribute to a greener, safer and more efficient future.

100%

of Engineering's research impact rated 'world-leading' or 'internationally excellent'

Research Excellence Framework (REF), 2021