Our facilities

Explore the facilities our Department of Aeronautical and Automotive Engineering has to offer.

We have an extensive range of laboratory facilities, offering students, researchers and staff an excellent environment in which to study and work.

We offer undergraduate, postgraduate, research students and staff an excellent environment in which to study and work. Our 360° views below allow you to see inside some of our state-of-the-art laboratories and teaching facilities.

Our major laboratory facilities

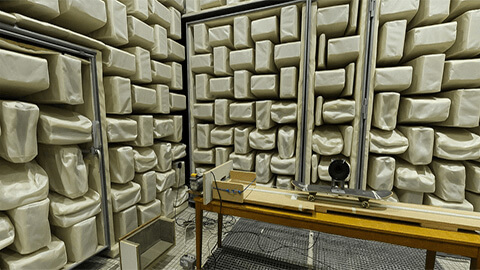

Acoustics and Vibration Laboratory

With full anechoic chamber and reverberation room: the building incorporates a specialised suspension system to isolate the facility from external ground vibration.

Aeronautical Propulsion Test Cells

Two test cells for high-pressure (up to 8 bar) nozzle experiments, and the running of small-scale gas-turbine engines.

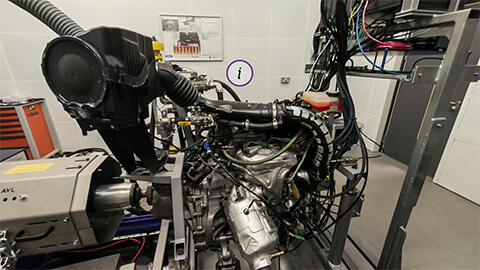

Automotive Powertrains Laboratory

Eight engine test cells and a chassis dynamometer; this includes various optical engines and optical diagnostics equipment, new transient engine dynamometer, CVS sampling and HORIBA emissions analysis equipment. The lab is run jointly with the School of Mechanical and Manufacturing Engineering.

Autonomous Systems Laboratory

Including indoor flight test environments with the support of Vicon optical tracking systems, fully instrumented ground vehicles, small-scale helicopters, fixed-wing aircraft, and autopilot development environments.

Display and Demonstration area

Adjacent to the main department entrance, this incorporates various hardware exhibits of aeronautical and automotive systems technology, including the full-scale Hawk 200 Aircraft.

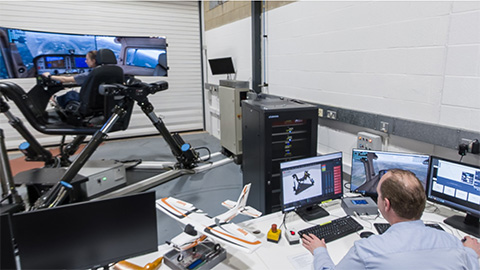

Dynamics and Control Laboratory

With new fully instrumented 6-axis flight/car simulator, four-poster vehicle road simulator, and small-scale servo-hydraulics rigs.

Electronics Workshops

Technician-led lab space for student projects and research work.

Batteries and Hydrogen lab

A hydrogen safe laboratory for testing hydrogen fuel cells, electrolysers and hydrogen combustion. Climatic battery testing facilities for multi-channel single cell degradation testing and higher power battery module testing.

Lift bay

For vehicle set-up and instrumentation.

Mechanical Workshops

Technician-led lab space for student projects and research work.

PC Computer Laboratories

With 79 individual workstations available running a range of specialist engineering software.

Rolls-Royce UTC Laboratory

Comprising four purpose-built test cells for isothermal measurements on complex combustion chamber geometries and other gas-turbine engine components. Instrumentation comprises a range of advanced probes, hot wire and optical instrumentation used for flow-field surveys.

Structures Laboratory

Including facilities for composite structures manufacturing, dynamic drop testing and ultrasonic analysis.

Undergraduate Teaching Laboratory

For small-scale manufacture and testing of structures, design and make projects, and dynamics and control undergraduate experiments.

Wind-Tunnel Laboratory

Incorporating a new low-speed aeronautical/automotive tunnel, plus two smaller subsonic tunnels and a smoke visualisation tunnel.

Water tunnel laboratory

With LDA/PIV systems for flow measurement and visualisation.

Wood and Plastics Workshop

Technician-led lab space for student projects and research work.