Smartroof KTP

Working alongside a renowned roof builder to automate the design of factory manufactured roofs.

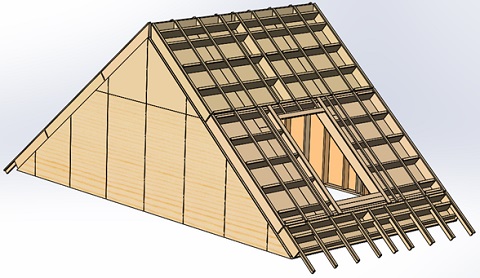

Roofs of the future won’t be built on site by builders, but instead in factories, where quality control and efficiencies of scale can be maintained.

This project explores how the design process for factory manufactured roofs could be made more efficient, allowing a seamless and largely automated flow from initial customer enquiry to manufacturing of the roof itself.

This project is a KTP (Knowledge Transfer Partnership) between Loughborough University (Dr Russell Lock – Computer Science, Prof Sergio Cavalaro – School of Architecture Building and Civil Engineering) and Smartroof, a subsidiary of Keystone Group.

While Smartroof have been manufacturing roofs in factories for some time, the roof design process has been a largely manual process, due to the variation between roofs built for different house types by different house builders. This project has put in place automated design functionality built upon the industry standard SolidWorks application. Based on a number of inputs we can produce not only the quotation cost for that roof, but also the engineering diagrams to produce it, in 3d, along with a set of data files for the automated manufacturing equipment necessary to produce the roof. The new Smartroof system, now in testing will reduce the design time for a roof from several hours to just a few minutes, providing a quantum leap in manufacturing automation.