Advanced Manufacturing

Manufacturing has been an integral part of Loughborough University since it was founded in 1909 as a Technical Institute with an Instructional Factory. Today our focus is on Metrology and Measurement, Intelligent Automation and Circular Economy and Sustainability.

Loughborough University is at the forefront of research tackling some of society’s most significant cross-sector and interdisciplinary challenges, including the future of Smart Manufacturing and the transition to a Circular Economy. Our key strengths include Collaborative Robotics, Intelligent Autonomous Systems and Sustainable Manufacturing. By applying fundamental science, we are driving the development of cutting-edge, next-generation manufacturing processes and technologies.

The key aims of Advanced Manufacturing at Loughborough University are to enhance capabilities, boost productivity and improve quality, whilst prioritising resilience and sustainability to shape the future of manufacturing.

Our areas of expertise

Metrology and Measurement

Our research focuses on advancing precision measurement technologies critical in complex high-value manufacturing processes.

Intelligent Automation

Our research focuses on intelligent automation solutions that deliver breakthroughs in productivity, agility, efficiency and resilience in Advanced Manufacturing.

Circular Economy and Sustainability

Our research supports eco-friendly manufacturing processes, minimising environmental impact and enhancing sustainability

Fundamental Research

Our research spans Additive Manufacturing, Intelligent Automation and Sustainable Manufacturing, driving innovation across various industries.

- In Additive Manufacturing, we work on cross-disciplinary projects in communication, electronics, prosthetics, biomaterials, aerospace, and automotive, focusing on sustainability and the mechanics of materials

- Our Intelligent Automation research focuses on industrial robotics, emphasising how humans can collaborate effectively with future automation systems.

- In Sustainable Manufacturing, we develop technologies for designing, producing, consuming, and disposing of products that meet customer needs while adhering to environmental, ethical and legislative standards.

Key projects

EPSRC Manufacturing Research Hub (RESCu-M2)

Robotics, Automation & Smart Machine Enabled Sustainable Circular Manufacturing & Materials

The RESCu-M2 manufacturing hub aims to transform the sustainable use of critical materials, whilst improving the productivity through a transition to circular economy and taking advantage of the latest advancements in Intelligent Automation.

Re-Imagining Photovoltaics Manufacturing

An ambitious project that is developing new material deposition and laser-based annealing techniques for photovoltaic materials. These new manufacturing processes will enable exciting new designs and applications of solar panels for decarbonising energy supply.

Centre for SMART

Sustainable Manufacturing and Recycling Technologies (SMART) is a research and development centre with a mission to advance technologies related to sustainable manufacturing and to promote effective end-of-life product retirement strategies in response to european legislation and corporate social responsibility requirements.

Intelligent Automation Centre

Develops innovative Intelligent automation solutions to drive breakthroughs in productivity, agility, efficiency and resilience. By closely collaborating with our industrial partners, research & technology organisations and academic institutions, we ensure excellence from the original concept through to industrialisation.

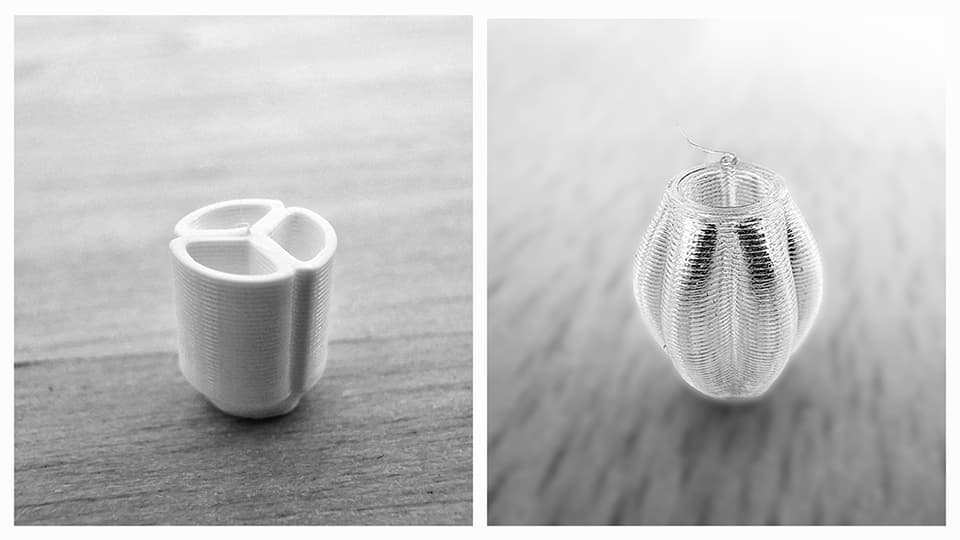

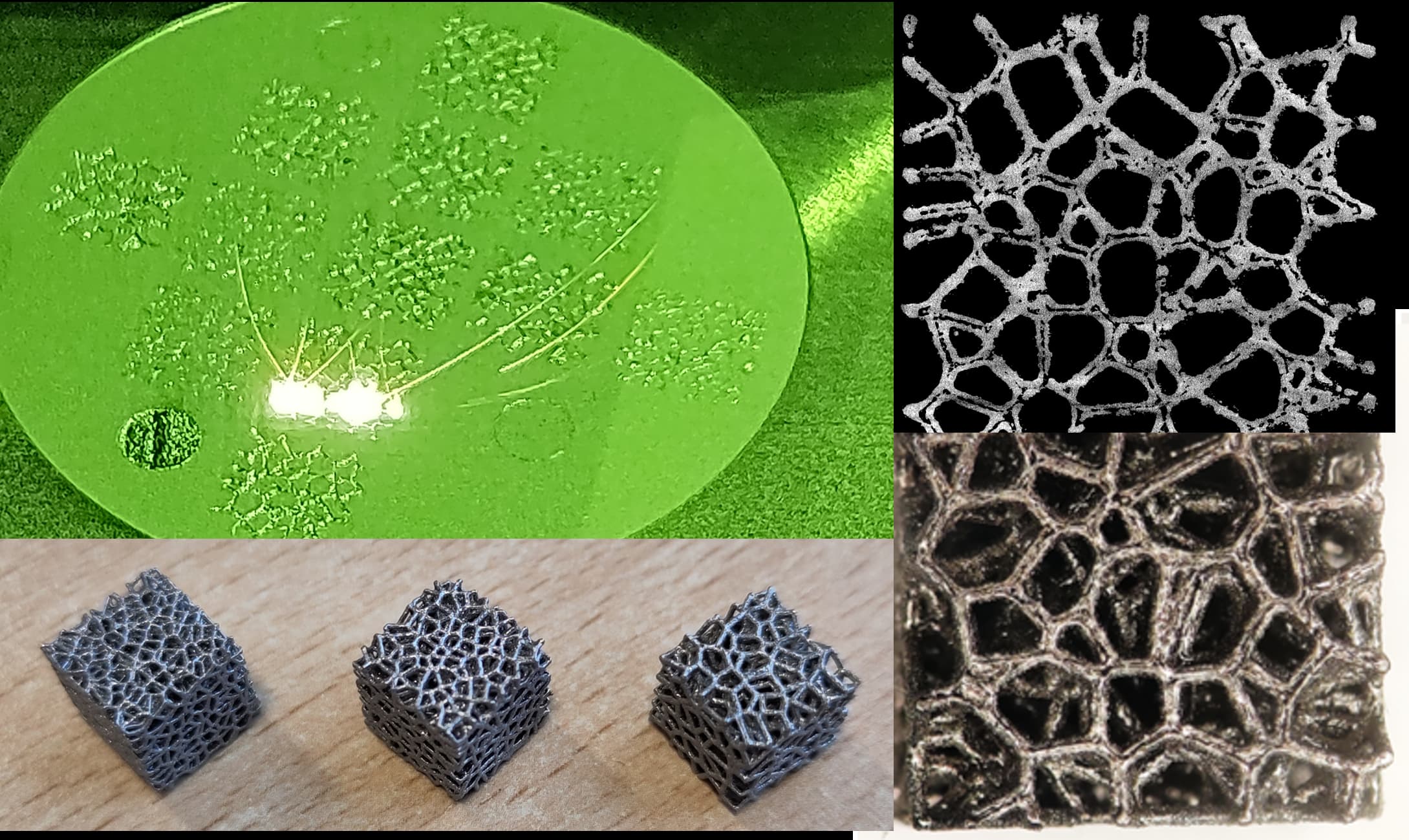

Unconstrained design for Additive Manufacturing

FullControl GCode Designer allows users to define print paths using a variety of feature types. It offers complete control over every aspect of the printing process for each line in the print path, and has evolved iteratively to make this detailed design process manageable, even for structures with thousands or millions of lines of GCode.