Design facilities

Our £21M, purpose-built Design building provides a truly state-of-the-art teaching and learning environment.

Within the walls of this building is everything our students need to develop into skilled, highly sought-after graduate designers.

Knowledge and skills advancement are at the centre of everything we do, pushing innovation and creativity to its highest potential. Designed by Burwell Deakins Architects and built by Shephard Construction, our fantastic building houses industry specification machinery, purpose-built teaching areas and specialist laboratories, in addition to design studios, computer and prototyping suits, and areas for display and interaction.

Our facilities...

Studio spaces

The design of our building has collaborative working at its heart, providing an inspirational environment for those within it. Our large, bright, and airy studio spaces are the perfect setting for a variety of independent and group work projects.

CAD/CAM area

This area houses the machinery required for Computer Aided Design/Manufacturing and 3D cutting of metals and plastics. The equipment available includes XYZ Vertical Computer Numerical Control (CNC) milling machines.

Rapid prototyping area

This area houses our additive manufacturing 3D printers. Students can realise the designs of their 3D CAD models in physical 3D plastic form; they can be used for a variety of solutions such as electronic product casings and medical equipment parts.

Engineering machine workshop

This specialist workshop is where students can carry out precision cutting of metals and plastics using lathes, milling machines, drills, and grinders. The equipment here is used for prototyping items such as crusher mechanisms and injection moulding tools.

Metal fabrication workshop

This room is used for the fabrication, cutting, brazing/welding and assembly of metal prototypes. Students are taught how to use hand tools, guillotines, and brazing techniques to form and join sheet metal. A prototype recently created in the workshop was for a baby pram wheelchair attachment.

Multi-materials workshop

This workshop is used for the hand and machine modelling of artefacts and prototypes. It contains 24 large workbenches that are used for wood and foam working, as well as vacuum forming machines, plastic welders/folders and drills.

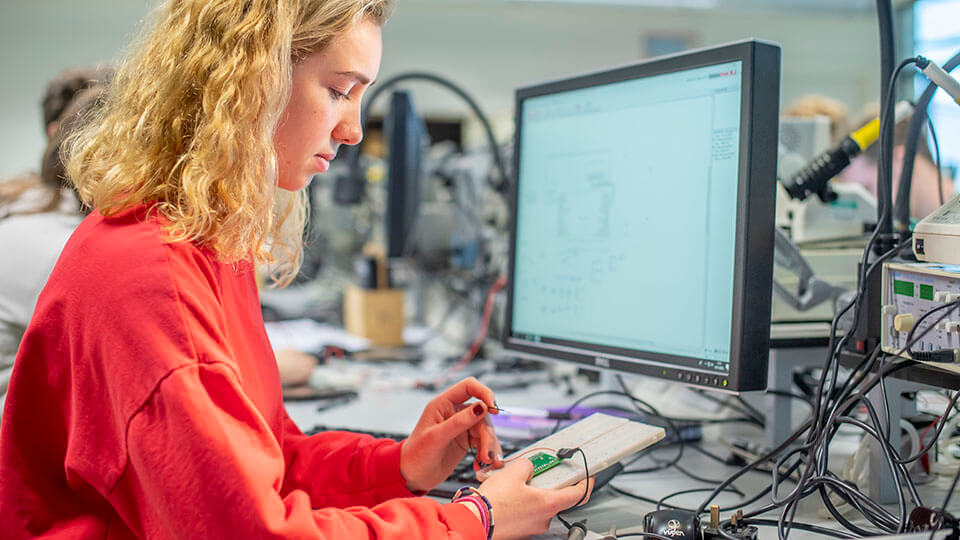

Electronics laboratory

This space is used to design, test, and build electronic project solutions. It contains IT equipment and CAD software for drawing Printed Circuit Boards (PCB), in addition to modern PCB manufacturing facilities including surface mount technology and test equipment.

Mac and PC labs

Our large Mac (pictured) and PC suites provide students with access to all the design, ergonomic, and UX software required for their studies. The PC suite is a dedicated 24-hour laboratory, which comes in handy for most of our students at some point during their studies.

Lecture theatre

The lecture theatres within our building are fully equipped with projectors, whiteboards, and Wi-Fi – everything you need to learn the important theory and cutting-edge research behind design processes.

Environmental ergonomics laboratory

This facility is used to study the interaction of people with their physical environment, from comfort to stressful experiences. Our two climatic chambers create artificial climatic control conditions, working between -300C to 5000C and with the ability to simulate altitude, wind, and radiation.