Facilities

Digital

We use industry standard software as well as working with open source software tools, such as 'Full Control', to automate processes and have created a digital workflow for delivering hybrid manufacturing for concrete (3D Printing and milling).

Materials

We have a full civil engineering materials laboratory to support materials development, supported by the UKCRIC National Facility for Infrastructure based at Loughborough, collaborations with Our Department of Chemistry and access to the Loughborough Materials Characterisation Centre.

Process

Our flexible production facility can be adapted to explore a range of automation tasks. It comprises of two ABB 6640 Robots, with ABB MID 2000 Rotary Unit, allowing Reach up to 2.8m with robot and MID payloads of 185kg and 2000kg respectively.

We can implement 1K and 2K (accelerated set for high build rates (4m vertical height per hour) mix design both batched and through continuous mixing when 3D Concrete Printing. Are systems are integrated for milling and practiced at hybrid production of large concrete parts. Dynamic mixing and milling equipment supplied by Concrenetics.

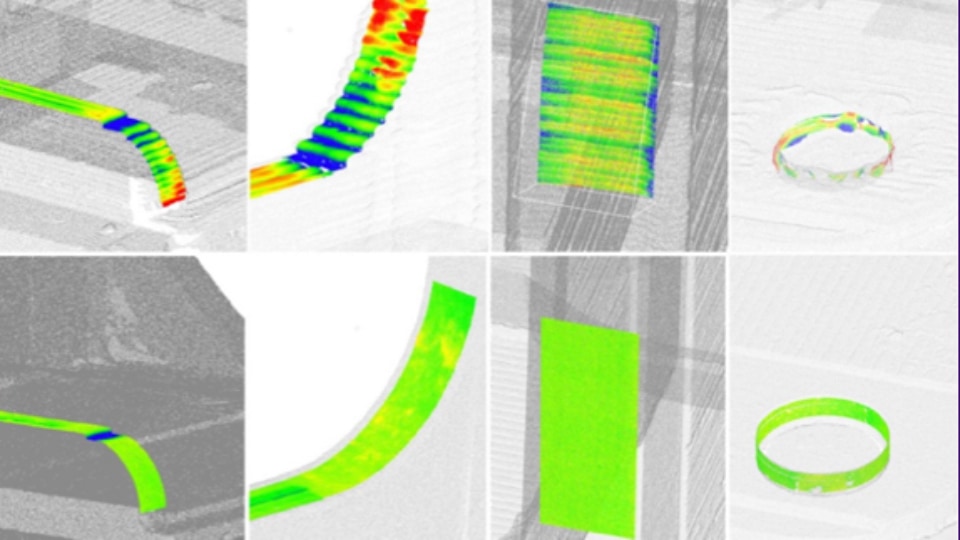

Measure

We partner with Intelligent Automation at Loughborough for automation and metrology. We have a range of optical measurement systems, from high accuracy laser (Micro Epsilon 2900-50, XXX), through large scale structured light (in house custom build) as well as surface interrogation (Alicona Infinitefocus G4, Talysurf CLI 2000) and robot motion tracking (Optitrack) which allow us to explore all scales of operation and geometric and surface quality of manufactured parts.