About Additive Manufacturing

Directed Energy Deposition

Directed Energy Deposition (DED) covers a range of terminology: ‘Laser engineered net shaping, directed light fabrication, direct metal deposition, 3D laser cladding’ It is a more complex printing process commonly used to repair or add additional material to existing components (Gibson et al., 2010).

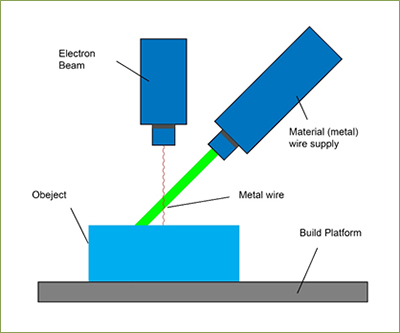

A typical DED machine consists of a nozzle mounted on a multi axis arm, which deposits melted material onto the specified surface, where it solidifies. The process is similar in principle to material extrusion, but the nozzle can move in multiple directions and is not fixed to a specific axis. The material, which can be deposited from any angle due to 4 and 5 axis machines, is melted upon deposition with a laser or electron beam. The process can be used with polymers, ceramics but is typically used with metals, in the form of either powder or wire.

Typical applications include repairing and maintaining structural parts.

Direct Energy Deposition – Step by Step

- A4 or 5 axis arm with nozzle moves around a fixed object.

- Material is deposited from the nozzle onto existing surfaces of the object.

- Material is either provided in wire or powder form.

- Material is melted using a laser, electron beam or plasma arc upon deposition.

- Further material is added layer by layer and solidifies, creating or repairing new material features on the existing object.

Technical Info

The DED process uses material in wire or powder form. Wire is less accurate due to the nature of a pre- formed shape but is more material efficient when compared to powder (Gibson et al., 2010), as only required material is used. The method of material melting varies between a laser, an electron beam or plasma arc, all within a controlled chamber where the atmosphere has reduced oxygen levels. With 4 or 5 axis machines, the movement of the feed head will not change the flow rate of material, compared to fixed, vertical deposition (Gibson et al., 2010).

Whilst in most cases, it is the arm that moves and the object remains in a fixed position, this can be reversed and a platform could be moved instead and the arm remain in a fixed position. The choice will depend on the exact application and object being printed. Material cooling times are very fast, typically between 1000 – 5000 degrees celsius / second (Gibson et al., 2010). The cooling time will in turn affect the final grain structure of the deposited material, although the overlapping of material must also be considered, where the grain structure is changed as the overlapping can cause re-melting to occur, resulting in a uniform but alternating micro-structure. Typical layer thicknesses of 0.25 mm to 0.5 mm (Gibson et al., 2010).

Machine Example:

|

Machine |

Area |

Layer Thickness |

Print Speed |

|

Insstek MX3 |

1000 x 800 x 650 mm |

0.089 - 0.203 mm |

2 layers/minute |

Materials

The Electron Beam Melting process uses metals and not polymers or ceramics.

Metals: Cobalt Chrome, Titanium (EBM - Built Materials, 2014).

Pros / Cons

Advantages:

- Advantages of DED

- Ability to control the grain structure to a high degree, which lends the process to repair work of high quality, functional parts

- A balance is needed between surface quality and speed, although with repair applications, speed can often be sacrificed for a high accuracy and a pre- determined microstructure (Gibson et al., 2010)

- Finishes can vary depending on paper or plastic material but may require post processing to achieve desired effect

- Limited material use

- Fusion processes require more research to further advance the process into a more mainstream positioning