About Additive Manufacturing

What is Additive Manufacturing?

Everybody recognises the term 3D printing nowadays but what many people mean when talking about 3D printing is actually one of the several Additive Manufacturing (AM) processes. However, as 3D Printing is an important process in the AM family, → The 7 Processes, it will be used here to explain the basic steps in the AM process.

So how exactly does Additive Manufacturing work?

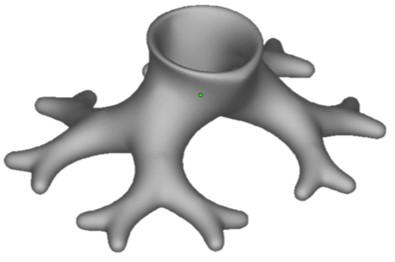

The first step is to create a 3D model of the object to be printed. This model can be designed with computer-aided design (CAD) software or through reverse engineering techniques by for example using an object laser scanner (Rosen et al., 2010).

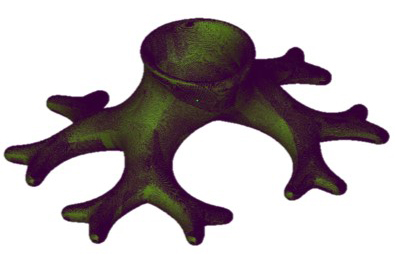

The CAD file is then converted to a standard additive manufacturing file format - usually an STL file. This step is regarded as the simplest (Chua et al., 2010). Conversion to a STL file will tessellate shapes and the time needed to do this depends on PC power and model complexity. The file is then digitally sliced into layers.

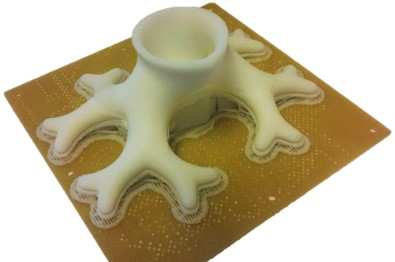

The third stage requires the transfer of the STL file and setting up of the machine. In order to print economically i.e. maximise cost savings and reduce material waste (Chua et al., 2010), the positioning and sizing of the object on the build platform should be checked – usually multiple parts are printed in one go.

In the fourth step, the machine which is only controlled by a computer builds the model layer by layer. The layer thickness dictates the final quality and depends on the machine and process. For Fused Deposition Modelling a layer thickness of 0.254 mm is typical, for Stereolithography printing can result in a quality of 0.05 – 0.1 mm (Chua et al., 20010). The size of a model depends on the machine size.

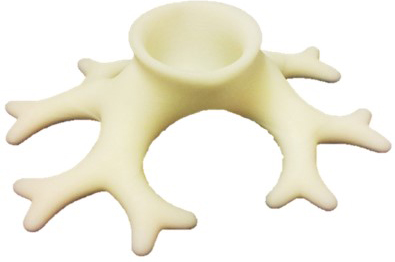

After building the part and potentially applying cooling and curing periods, the model can be removed from the machine. Additional post processing can occur such as cleaning, polishing, painting and finishing of the surface to the desired standard. This may involve the use of other machines and tools.

Advantages of AM

- Greater design ability. The technology allows assemblies to be printed in one process and organic shapes to be easily produced. Traditional constraints of manufacture are reduced or eliminated.

- Unlike many widely used manufacturing techniques such as injection moulding, no tooling is required, which can be a barrier to production due to the high cost.

- Anywhere manufacture. Parts can be sent digitally and printed in homes or locations near to consumers, reducing the requirement and dependence on transport

- Compared to conventional techniques with more geometric limitations, additive manufacturing can produce models quickly, in hours, not weeks.

- Fewer resources for machines and little skilled labour when compared to conventional model making craftsmanship.

- Customisation - Particularly within the medical sector, where parts can be fully customised to the patient and their individual requirements.

- Efficient material use due to the exact production of parts and no overproduction based on estimated demand.

- Commercial advantage and increased competitiveness, in the form of reduced costs and risk, as the development time from concept to manufacture is minimised.

- Material efficiency. Material required matches material used. Support material and powder can often be recycled at source, back into the system.

- Environmental benefits. The emissions from trans- port are reduced because of the ability to manufacture anywhere.

- With increasing numbers of machines, 3D printing is becoming more affordable, whereas injection moulding machines remain relatively expensive and inaccessible.