Research

Structured Antibacterial Coatings

Polymer particles dispersed in water, also known as latex, are the main component of many products of industrial relevance such as paints, coatings, inks or adhesives. When one of these products is applied on a surface, the first stage of latex film formation is the drying of water and particle packing. Achieving control over this process and being able to structure the film “on demand” is paramount to tailor its final properties.

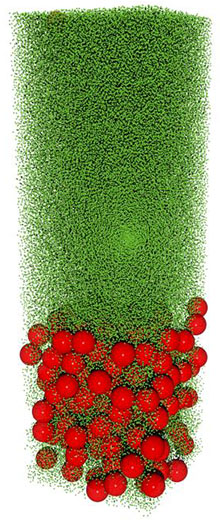

When drying waterborne blends of large and small particles, an osmotic pressure develops that drives the large particles away from the descending film surface. This results in a stratified coating, with a layer of small particles on top and another of large particles below. Thus, the coating can be designed so that its surface properties (e.g. tack, wetting, gloss) differ from the bulk properties. It is a simple, single-step, and environmentally friendly process which does not require any demanding conditions. We are currently exploiting this effect to impart antibacterial functionality to the top surface of coatings. This is being carried out by using two different approaches, based on the addition of either nanosized bactericidal agents to kill bacteria or antifouling particles to prevent bacterial adhesion. This work is a continuation of the research carried out at the University of Surrey in the context of an EC FP7 project (http://www.bbc.co.uk/news/science-environment-35871261).

When drying waterborne blends of large and small particles, an osmotic pressure develops that drives the large particles away from the descending film surface. This results in a stratified coating, with a layer of small particles on top and another of large particles below. Thus, the coating can be designed so that its surface properties (e.g. tack, wetting, gloss) differ from the bulk properties. It is a simple, single-step, and environmentally friendly process which does not require any demanding conditions. We are currently exploiting this effect to impart antibacterial functionality to the top surface of coatings. This is being carried out by using two different approaches, based on the addition of either nanosized bactericidal agents to kill bacteria or antifouling particles to prevent bacterial adhesion. This work is a continuation of the research carried out at the University of Surrey in the context of an EC FP7 project (http://www.bbc.co.uk/news/science-environment-35871261).

The technology has attracted the interest of several of the most relevant companies in the paints and coatings sector (e.g. AkzoNobel, Sherwin-Williams) and we are working with them to develop new products and applications.