Research degrees

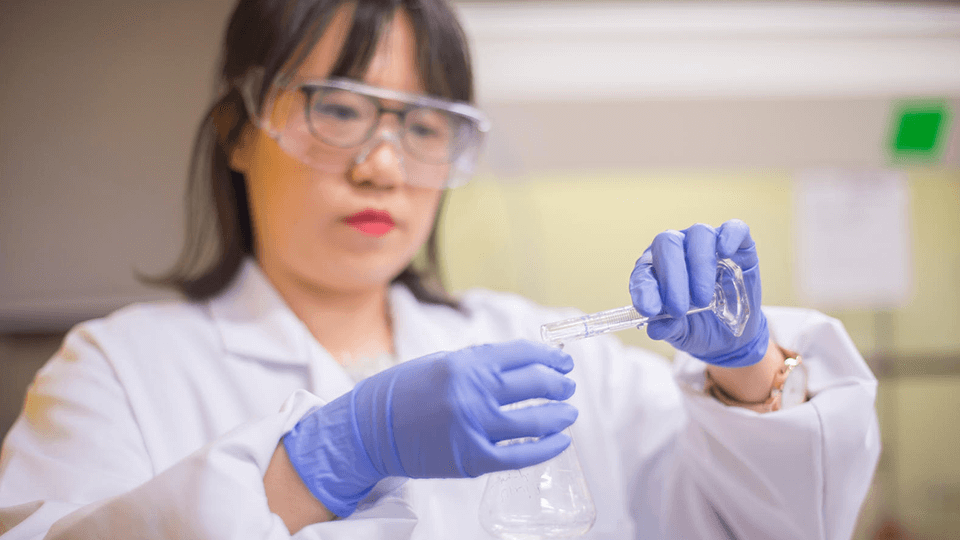

Benefitting from the expertise and considerable experience of the Department's staff, our thriving community of postgraduate research students are provided with an intellectually challenging and rewarding experience during their time with us.

We offer both PhD and MPhil programmes, along with the option for part-time study, giving you flexibility and allowing you to conduct unique research for solving real-life issues.

Benefiting from the expertise and considerable experience of the Department’s staff, our thriving community of postgraduate research students provides an intellectually challenging and rewarding experience.

If you are interested in working with a particular member of staff as part of your postgraduate research study, please contact the academic directly. Our academic staff are very pleased to help prospective students develop their research proposals as part of their application process. We also welcome prospective research students to visit the Department to see the facilities and to meet the academic staff.