Case study 1

Battery-electrolysers

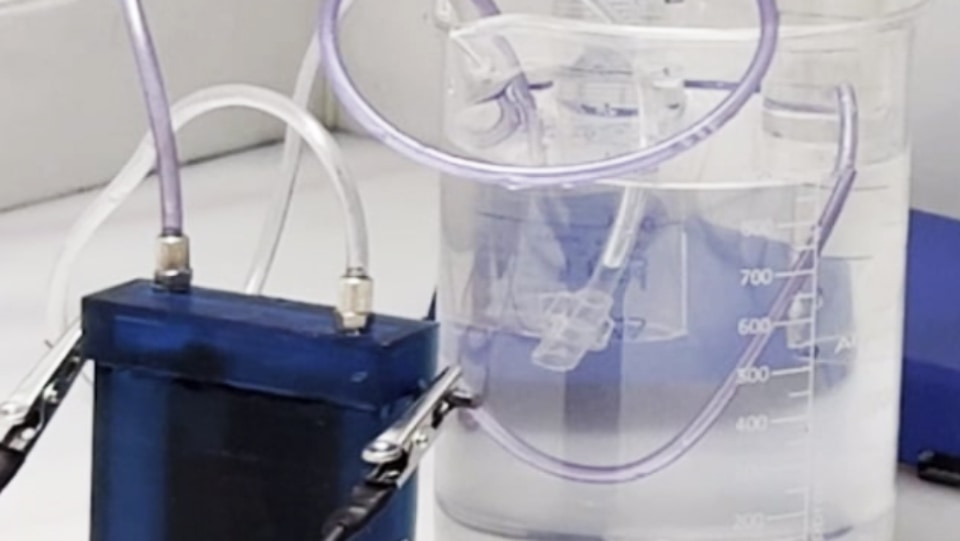

This is an example of work within the team looking at low-cost production of hydrogen through a battery-electrolyser (similar functionality as the Delft-developed battolyser but using different chemistries). It starts life as a battery or flow battery that can produce hydrogen under electrolysis. The water consumption of this reaction is compensated by adding water to the electrolyte to avoid a concentration increase of the electrolyte that would subsequently affect the battery-electrolyser's chemistry.

The battery-electrolyser works by:

- Discharging as a battery when electricity demand exceeds generation

- Charging as a battery

- Use excess electricity to produce hydrogen

A battery-electrolyser was first developed at Delft University by Dr. Fokko Mulder et al. based on Nickel-Iron batteries. Loughborough has been investigating alternative battery-electrolyser chemistry solutions using more abundant materials.

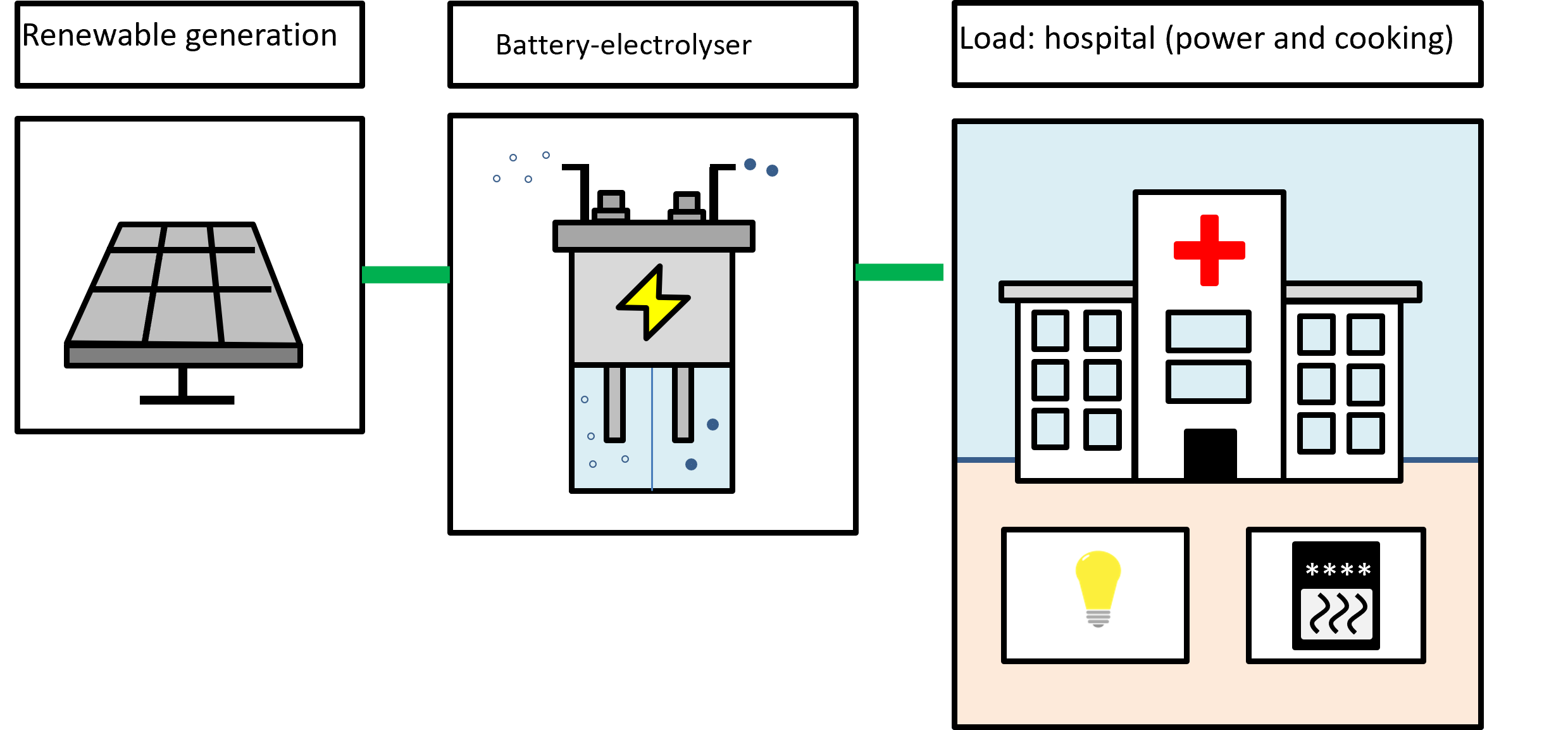

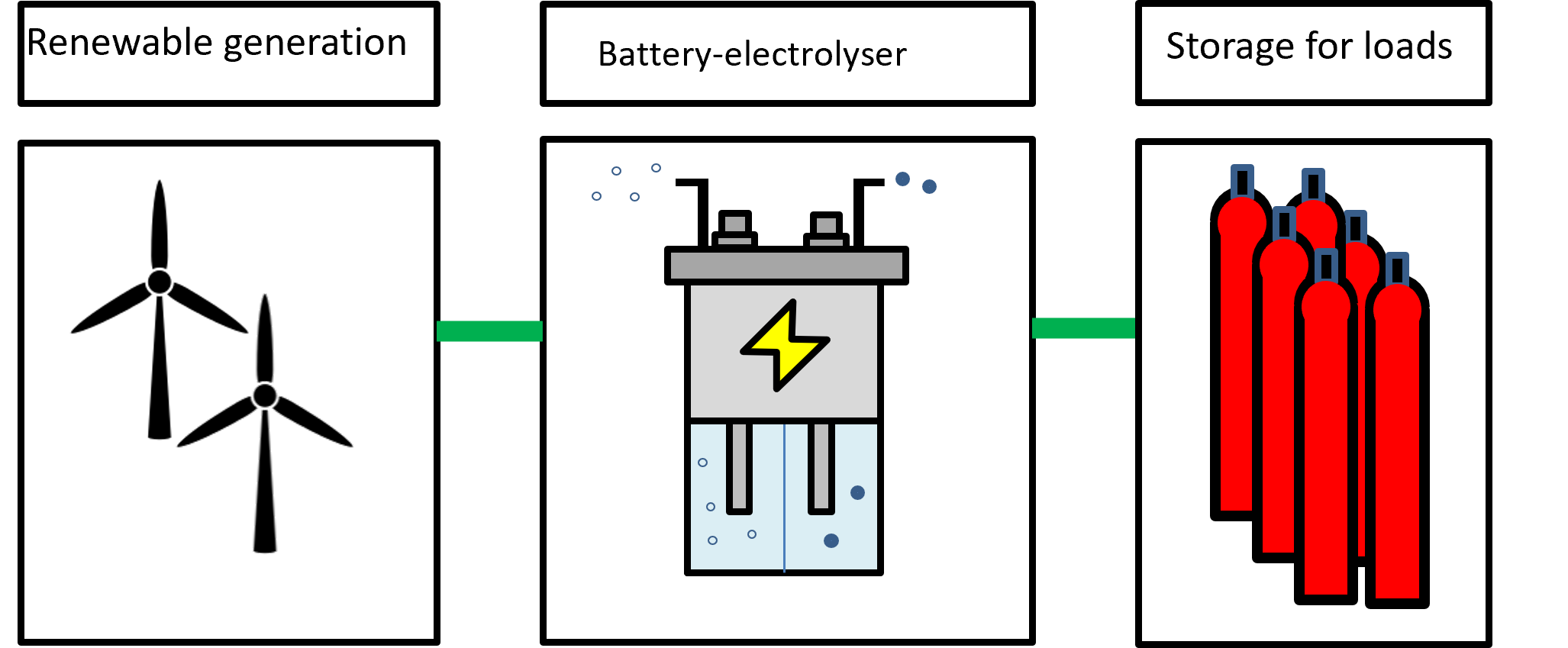

We are looking at two different use cases, as shown below.

Battery-electrolysers in microgrids

Battery-electrolysers using curtailed wind power

Our work includes, but is not limited to:

- Early TRL chemistry investigation

- Measurement and testing

- Modelling

- Prototyping

- Business case and use development