Green Hydrogen Group

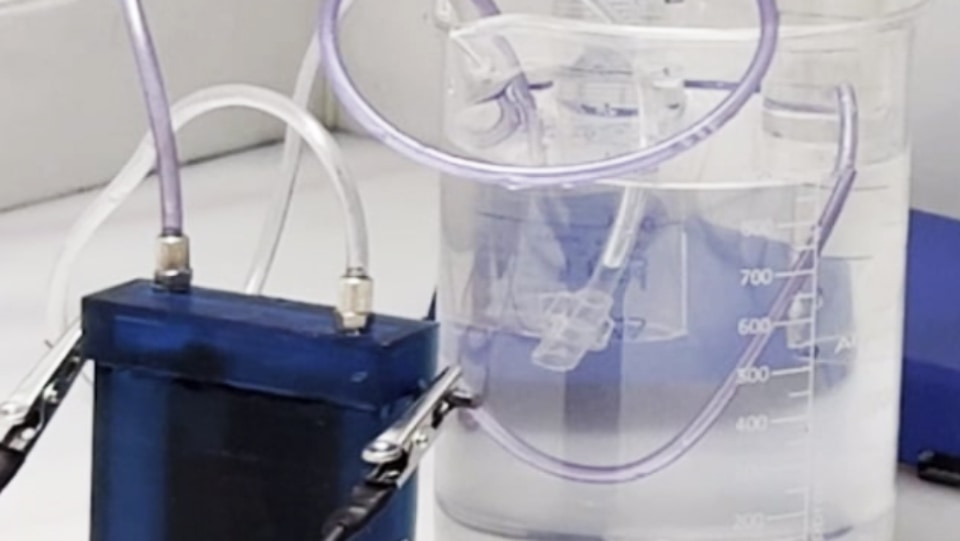

This group is focused on low-cost green hydrogen from production through to use.

Our aim

To research and develop all aspects of low-cost green hydrogen from fundamental chemistry, physics and engineering through to high level TRL demonstrators.

Our research areas encompass all areas of hydrogen from production through to end use including storage, distribution, combustion, policy, economics and safety, sustainability analysis and lifecycle management.

Our research goals

- Low-cost design e.g. through not using exotic materials

- Sustainable use of materials e.g. abundant materials

- Develop products with good life span (robust chemistry), ease of use and repair

- Recyclability

- 15-year maximum payback period