Research

The long-standing collaboration has enabled the I&RC to use its expertise and capability to investigate innovative technologies in a variety of research areas closely aligned with industry and government goals. Over many years projects have covered the research themes of control, thermal management, after-treatment and more recently hybridisation, materials, data analytics and digitisation which have earned academic respect, delivering commercial value as well as far reaching economic and societal impact.

Research themes I&RC address include but are not limited to:

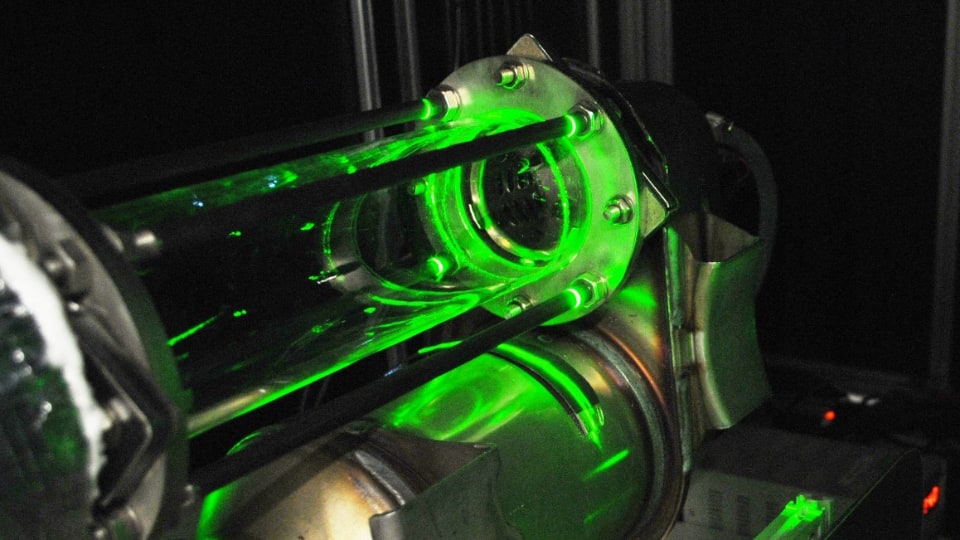

Boost and energy recovery

The trend to downsized engines places the emphasis on air system performance. Research topics include managing high levels, boost and rapid changes. High dynamics requirements require innovation on control systems technology and attention to abnormal conditions such as surge. Air systems provide a natural home for development in energy recovery, and component design allied with control system technology offers substantial benefits.

Thermal management

Improved thermal management is made necessary by high thermal load coming from downsized combustion systems. Reducing the mass and complexity of cooling systems is an essential step towards fuel economy. Fundamental issues typified by pulsating flow heat transfer provide a focus for fundamental research that can bring immediate benefits to product development.

Control

The increasing number of degrees of freedom in a modern engine places demands on the control system to manage optimal conditions under the transient loads expected in machinery. The need to maintain low emissions and high fuel economy leads to unique control solutions which need both implementation and test.

After-treatment

An after-treatment system represents a significant cost and complexity in a modern engine system. Research into fluid flow, thermal phenomena, spray generation and control methods will lead to reduced complexity and cost, with improvements in reliability.

Mechanical design

While engine design methods are well established, the increasing thermal loads and downsizing are increasing the mechanical stresses on components. Bearings, cylinder heads, valves and boost devices are all vulnerable and to increase performance while maintaining manufacturing costs innovative design and deployment of materials is vital.

Modelling

The use of advanced modelling and simulation tools is essential in modern engineering design. When performed early in the design cycle these tools allow for efficient exploration of the design space and significantly reduce the number of expensive hardware iterations. The use of these tools does however require a detailed understanding of the physical phenomena being modelled and the provision of high-quality validation data to gain confidence in their application. Fundamental research into sprays, flow, combustion, heat transfer and advanced material properties has supported the advancement of these tools in product development.

Hybridisation and energy recovery

Hybridisation is an important technology for reducing CO2 emissions in a modern engine system. The instant torque, high efficiency and energy recovery and storage attributes of an electrical system can be combined with the combustion engine to produce a more efficient system with increased performance. The ancillary systems such as coolant pumps and fans can also be electrified to reduce parasitic losses. Challenges include the integration, optimisation and control of hybrid systems to maximise the benefits without increasing system cost.