The Canopy is here!

The Canopy is the first of its kind and the result of five years of research funded by UK Research and Innovation. It demonstrates what is possible when you combine the flexibility of 3D concrete printing, with the precision of CNC milling.

The combination of processes enables a complete rethink of the design and delivery process, allowing unprecedented quality and degree of feature detailing which enables:

- Integration with other construction components through precise interfaces,

- Creation of structural joints to allow end-of-life disassembly, and,

- Seamless provision for mechanical and electrical systems.

Source: https://doi.org/10.1016/j.jobe.2025.112640

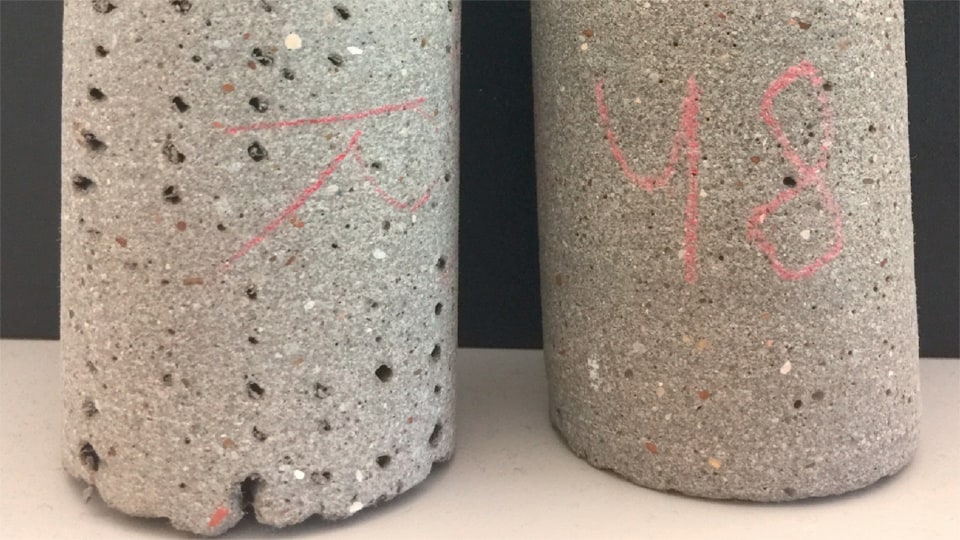

The manufacturing process begins by cutting a former to shape the double curved panel, 3-D printing is done in layers conformally with this layer, pausing to install reinforcement before finishing the printing. The process is paused while the concrete begins to set, and then the CNC milling is carried out producing the high degree of precision in the final part.

Source: https://doi.org/10.1016/j.jobe.2025.112640

The precision that can be reproduced is unprecedented, and allows for the integration of assembly components, joints, channels for lighting and cables as well as water handling features such as drip lines, and drainage – all with no additional manufacturing steps, no additional materials required. It can all be accomplished through digital automation and control.

Further information

More information on the canopy and associated research can be found in the following articles:

An introduction to the world of 3D concrete printing

And an introduction to the world of 3D concrete printing and the transformation to ‘hybrid’ manufacturing can be found in our online lecture by the project lead, Professor Richard Buswell, as well as a time-lapse video of the manufacturing process:

Credits

Project leadership: Loughborough University - Richard Buswell

Structural Design: Cundall - Rasti Bartek and Vera Sehlstedt

Architectural Design: Foster + Partners - Richard Maddocks and Marina Konstantatou

Production: School of Architecture, Building and Civil Engineering in collaboration with Intelligent Automation in School of Mechanical, Electrical and Manufacturing Engineering at Loughborough University - J.Dobrzanski, Jerry Xu, John Kolewole, Liam White, Mohammad Isa Nura, Abbdulaziz Alfarhan, Xingzi Liu, Sidou Lei, Connor Gill, with support from Lewis Darwin, Mark Whale, Matthew Biddulph, Neil Parkes, Dean Sandham, Richard Stanley, Lee Page and Jonathan Hales.

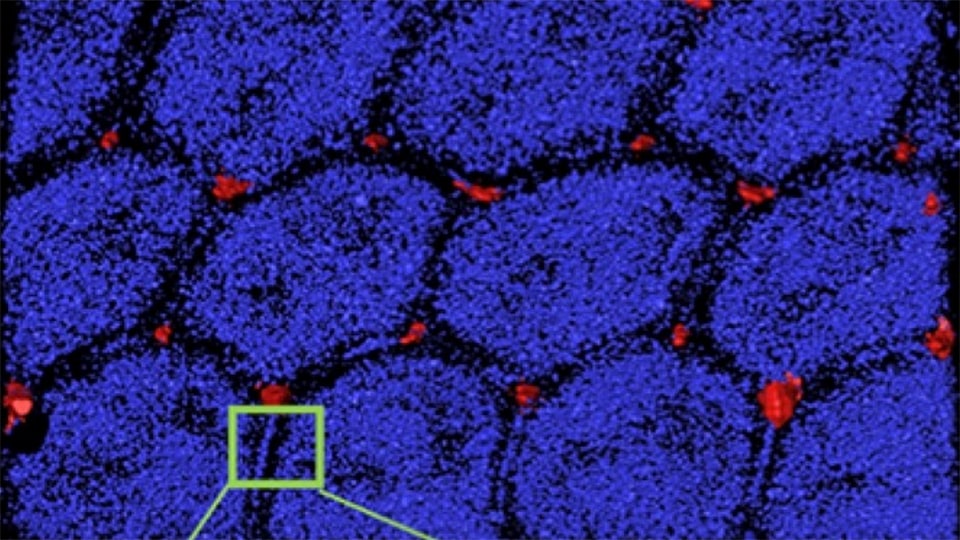

Supporting research project - academics: Richard Buswell, Peter Kinnell, Sergio Cavalaro, Simon Austin (Loughborough University, through UKRI awards EP/S019618/1 and EP/S031405/1) in collaboration with: Luca Susmel, John Provis (University of Sheffield) and Suzan Bernal (University of Leeds, through UKRI award EP/S019650/1); Dirk Engleberg, Phil Withers (University of Manchester, through UKRI award EP/S019731/1);

Supporting research project - industrial partners: Cundall, Foster+Partners, Autodesk, Elkem, Manufacturing Technology, British Standards Institute, ABB Group, Building Research Establishment, Skanska UK Ltd, IFSTTAR, Enabling Process Technologies, Urbastyle, Concrenetics and Synthomer plc.