It is crucial that small organic pharmaceutical molecules used in medicines are purified as the wrong chemical components in a drug can induce strong side effects or cause it to be harmful to humans.

More than 90% of small organic pharmaceutical molecules are purified by crystallisation – a process that allows a desirable substance to be obtained from an impure mixture by turning it into crystals.

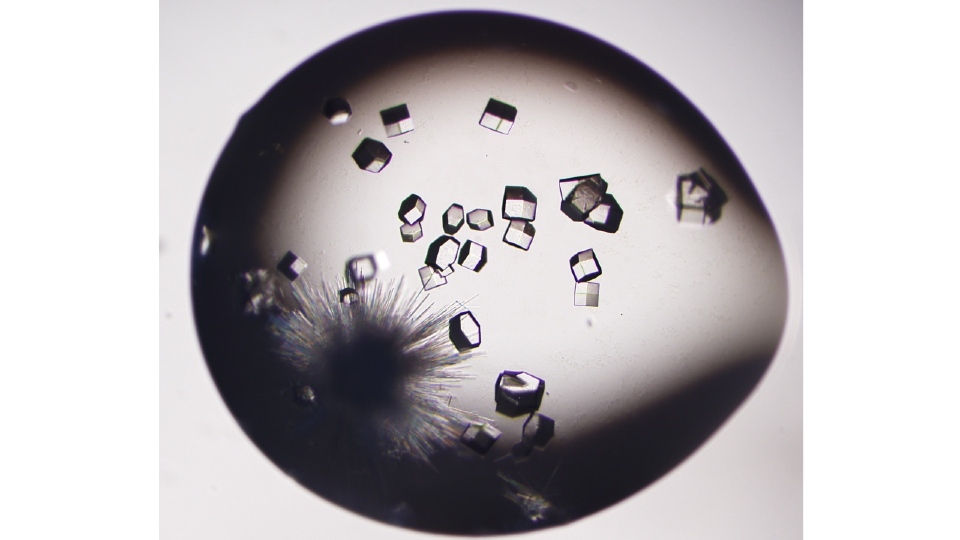

The process involves two main steps: nucleation (the first step and the one that determines the crystal properties, including purity) and crystal growth.

Despite the process being well-used, little is known about the pre-nucleation phase in crystallisation.

Dr Huaiyu Yang, of the Department of Chemical Engineering, says shedding light on this pre-phase is key to making potentially life-saving medications more affordable and accessible.

He explained: “The first step of nucleation is the formation of one very, very tiny crystal – known as a nucleus – in the solution.

“But what happens before this tiny crystal appears, such as how the liquid changes phase and how the solute molecules come together to form nuclei, is not clear.

“This is because they are so tiny and moving in the solution, making them hard to observe.

“It is important to better understand the pre-nucleation phase and nucleation process as it will allow better control of the crystallisation process.

“This control will decrease the cost of biomanufacturing, and therefore decrease the price of biopharmaceuticals.

“This will lead to an increase in survival rates of various diseases as currently, pharmaceuticals made using this process are very high in price so the project has the potential to make important medicines more widely available.”

To achieve this goal, the Royal Society has awarded funding to Dr Yang through their International Exchange Scheme.

Dr Yang will head Loughborough’s involvement in the exchange programme with Tianjin University, which will see academics (including PhD and postdoctoral students) travel between the UK and China to visit each other’s crystallisation teams and conduct two-to-three month-long projects at the partner university.

The researchers will use advanced equipment and technologies to track and observe behaviours of the nano-size scale (10-9m) pre-nucleation phase in different solutions.

Of the exchange project with Tianjin University, Dr Yang said: “I am very glad to have this funding, I hope it will promote the exchanging of research students and researchers between China and the UK, strengthening the international leading position of Loughborough University.

“It will also hopefully kickstart more international research activities and collaborations focused on healthcare – which is crucial to keeping the world healthy.”

Professor Junbo Gong, the Tianjin lead, added: “Tianjin University is home to the National Engineering Research Center of Industrial Crystallization Technology (NERCICT) – the only national-level incubation base in the field.

“To support the development of high-end functional crystal products and materials in medicine, food, and other industries, researchers have studied the mechanisms of industrial crystallisation processes, relevant system engineering, and industrialisation processes, leading to improved technologies and equipment.

“This collaboration will have large benefits on both sides of the collaborator, such as to exchange knowledge between two teams, to kickstart future research activities and collaborations, and to accelerate the collaborations between the Department of Chemical Engineering from Loughborough University and Tianjin University.”

Tianjin University’s involvement in the exchange project is funded by the National Natural Science Foundation of China.