WPL 0.04 Engineering Machine Workshop

Overview

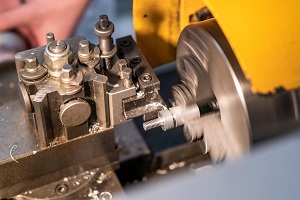

The Engineering Machine Workshop contains a range of manual and Computer Numerically Controlled (CNC) Machines to manufacture virtually any component imaginable.

In this workshop students can learn the techniques and skills needed to produce simple components and establish a basic understanding of manufacturing methods and limitations. These skills are built upon during their degree course, and further during their final year project if the student is required to manufacture components.

Since STEMLab opened, this workshop has evolved into a multi-material processing facility that enables students from wide-ranging disciplines to gain practical experience and exposure to areas outside of their own studies. As such, the workshop is central to Loughborough STEMLab's central ethos of cross-functional learning, providing opportunities for students from across disciplines to share knowledge and ideas which can be used to generate innovative solutions to real-world problems.

Extracurricular activities

In addition to its important uses in teaching and project work, the Engineering Fabrication Workshop will be used my members of Loughborough University student societies (such as Fighting Robot Society, Loughborough Space) and for students involved in Formula Student, the British Model Flying Association, and the IMechE Unnamed Aircraft Systems challenge.

What we teach

These labs are primarily used for the teaching of courses in Aeronautical and Automotive Engineering, Architecture, Building and Civil Engineering, Mechanical Engineering, Design, and Materials Engineering, as well as Bioengineering and Foundation Physics.

The workshop is available to students who need bench space for project work as part of their course, or those involved with various societies (such as Fighting Robots) and competitions (e.g. Formula Student).

What you learn

Two modules are taught in the Engineering Machine Workshop. The first is a taught module to introduce the equipment and basic manufacturing methods. Once a basic level of competency is reached students can use the facility (with supervision) to achieve their project objectives.

The second module is essentially a service provision for students without the necessary practical skills and knowledge to have products and components manufactured for them by our technicians.

Equipment

Equipment in these laboratories includes:

- Manual lathes and milling machines (for producing round or cylindrical components)

- Computer Numerically Controlled (CNC) centre lathe (for complex parts)

- CNC milling machine

- CNC machining centre

- Laser cutters (both class 4 lasers within a class 1 system; can cut MDF, balsa, leather, acrylic etc.)

- Water jet (to cut aluminium, steel etc.)

- CNC router (can be used for MDF, plywood, etc.)