About Additive Manufacturing

Sheet Lamination

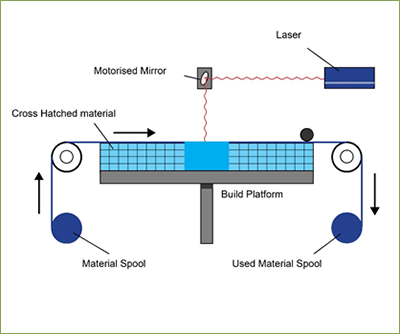

Sheet lamination processes include ultrasonic additive manufacturing (UAM) and laminated object manufacturing (LOM). The Ultrasonic Additive Manufacturing process uses sheets or ribbons of metal, which are bound together using ultrasonic welding. The process does require additional cnc machining and removal of the unbound metal, often during the welding process. Laminated object manufacturing (LOM) uses a similar layer by layer approach but uses paper as material and adhesive instead of welding. The LOM process uses a cross hatching method during the printing process to allow for easy removal post build. Laminated objects are often used for aesthetic and visual models and are not suitable for structural use. UAM uses metals and includes aluminium, copper, stainless steel and titanium (Ultrasonic Additive Manufacturing Overview, 2014). The process is low temperature and allows for internal geometries to be created. The process can bond different materials and requires relatively little energy, as the metal is not melted.

Sheet Lamination – Step by Step

- The material is positioned in place on the cutting bed.

- The material is bonded in place, over the previous layer, using the adhesive.

- The required shape is then cut from the layer, by laser or knife.

- The next layer is added.

- Steps two and three can be reversed and alternatively, the material can be cut before being positioned and bonded.

Technical Info

Laminating (LOM) is one of the first additive manufacturing techniques created and uses a variety of sheet material, namely paper. Benefits include the use of A4 paper, which is readily available and inexpensive, as well as a relatively simple and inexpensive setup, when compared to others.

The Ultrasonic Additive Manufacturing (UAM) process uses sheets of metal, which are bound together using ultrasonic welding. The process does require additional CNC machining of the unbound metal. Unlike LOM, the metal cannot be easily removed by hand and unwanted material must be removed by machining. Material saving metallic tape of 0.150mm thick and 25mm wide does however, result in less material to cut off afterwards. Milling can happen after each layer is added or after the entire process. Metals used include aluminium, copper, stainless steel and titanium. The process is low temperature and allows for internal geometries to be created. One key advantage is that the process can bond different materials and requires relatively little energy as the metal is not melted, instead using a combination of ultrasonic frequency and pressure (The Engineer, 2014). Overhangins can be built and main advantage of embedding electronics and wiring (Karunakaran et al., 2012). Materials are bonded and helped by plastic deformation of the metals. Plastic deformation allows more contact between surface and backs up existing bonds (Janaki Ram et al., 2007).

Post processing requires the extraction of the part from the surrounding sheet material. With LOM, cross hatching is used to make this process easier, but as paper is used, the process does not require any specialist tools and is time efficient. Whilst the structural quality of parts is limited, adding adhesive, paint and sanding can improve the appearance, as well as further machining.

Machine Example:

|

Machine |

Area |

Layer Thickness |

|

MCor Matrix 300 plus |

A4 paper: 256 x 169 x 150 mm |

0.1 mm – 0.19 mm |

Materials

Effectively any sheet material capable of being rolled. Paper, plastic and some sheet metals.

The most commonly used material is A4 paper.

Pros / Cons

Advantages:

- Benefits include speed, low cost, ease of material handling, but the strength and integrity of models is reliant on the adhesive used (Krar and Gill, 203)

- Cutting can be very fast due to the cutting route only being that of the shape outline, not the entire cross sectional area

- Finishes can vary depending on paper or plastic material but may require post processing to achieve desired effect

- Limited material use

- Fusion processes require more research to further advance the process into a more mainstream positioning