Research and specialist facilities

We have extensive facilities to support our research – including our Polymer Processing Laboratory, Materials Characterisation Centre, Soft Matter Synthesis Laboratory, Advanced Materials Laboratories, and Surface Engineering and Materials Degradation Centre.

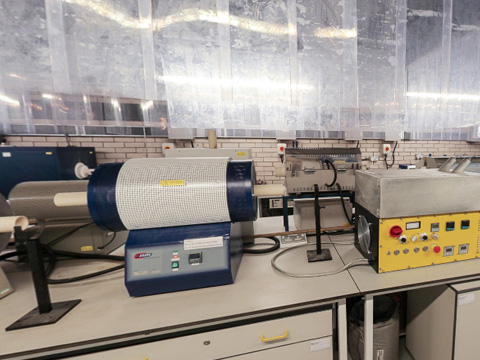

Polymer Processing

A key strength of our research profile has always been the ability to conduct investigations across polymer technologies including chemical synthesis, mixing and dispersion of novel additives, upscaling, industry-scale processing and progressing and component testing and characterisation.

Our Polymer Processing Laboratory houses a suite of state-of-the-art equipment for plastics and rubber compound preparation, injection moulding of plastics and ceramic powders, compression presses and several extrusion facilities – including single-screw units for sheet and blown film as well as twin-screw machines for high-speed compounding and rigid PVC processing.

Much of our research is application-oriented, including some longstanding collaborations with the packaging, building and construction, automotive, sport, defence and bio-medical sectors. Our new Polymer Composites Laboratory supports composite manufacturing research in materials engineering for the aerospace sector. These facilities are complemented by a range of rheometers – capillary, rotational and curemeters – for the assessment of flow properties as well as simulation software and test equipment in a temperature-controlled environment.

The scope of our expertise and equipment provides enormous opportunities for collaborative research programmes – supporting short-term contract and consulting activity as well as student projects. While much of our research is sponsored by the public sector authorities, we also collaborate with many companies along the component supply chain – including suppliers of polymers, additives and intermediates, component manufacturers and end-users.

Activities we address include but are not limited to:

- Processing of stimuli-responsive nano-scale fibres using electrospinning

- Orientation of disentangled ultra-high molecular weight polyethylene (UHMWPE)

- Characterisation of rheological behaviour of polymers for additive manufacturing

- Elastomer mixing & processing: novel fillers and their effects on mechanical and ageing properties

- Polymer-clay nanocomposites: compounding and thin-wall injection moulding

- Polymer rheology, process simulation and component optimisation

- Manufacturing processes to produce additives with enhanced functional performance

- Influence of processing on microstructure and mechanical performance of modified thermoplastics

- Novel routes to manufacture polymer nanocomposites

- Melt-state blending of biodegradable plastics to enhance mechanical performance

- Novel materials and process technologies for specific industrial sectors

Contacts

Academic staff:

- Dr Yi Liu (Main Academic Contact)

- Dr Xujin Bao

- Dr Helen Willcock

- Dr Fiona Hatton

- Dr Ignacio Martin-Fabiani

- Dr Elisa Mele

- Dr Simon Martin

- Dr Noreen Thomas

Research staff:

- Dr Carole Raymond - Visiting Research Fellow

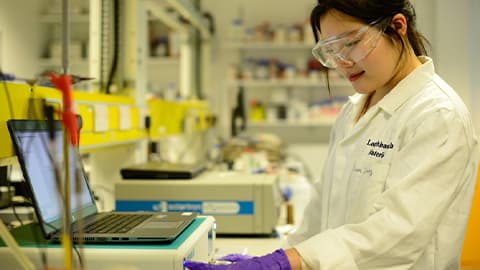

Loughborough Materials Characterisation Centre

The Loughborough Materials Characterisation Centre (LMCC) offers a wide range of analytical techniques. Its main areas of expertise are Electron and Optical Microscopy, Surface Analysis, X-Ray Diffraction and Thermal Analysis. The facilities are supported by a team of specialists ensure researchers to gain the maximum benefits from the instrumentation.

The LMCC also works with leading instrument manufacturers to help them improve their products and shift the boundaries in materials and analysis.

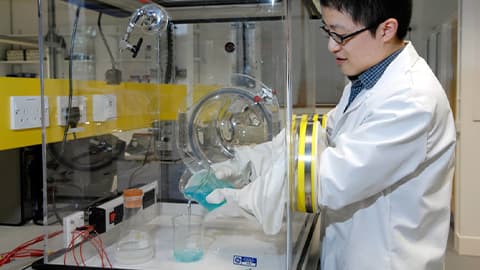

Soft Matter Synthesis Laboratory

Our Synthetic Labs are equipped to perform a wide range of reactions with solid, liquid and gaseous reagents, with control of pressure and temperature in air or other atmospheres. Chemicals sensitive to air and moisture are handled in a glove box or using Schlenk techniques. Steel and glass autoclaves allow synthesis with gaseous reagents with pressures up to 12 bars.

Facilities include:

- Schlenk lines

- Glove box

- Autoclaves

- Rotavapor

- Hot plates with magnetic stirrer

Advanced Materials Laboratories

Our Advanced Materials Research Laboratories include a bespoke suite of spaces, including those for polymer and composite synthesis and processing, ceramic processing, advanced testing and degradation studies and materials characterisation.

Facilities include:

| State-of-the-art facilities for sample preparation to enable advanced analysis | Equal Channel Angular Pressing Rig |

| Laboratory-scale dynamometer | Customised pin-on-disc tribometer |

| Electrophoresis deposition (EPD) for coating manufacture | Fibre-ceramics composite preform manufacture |

Furnace facilities (with and without controlled atmospheres)

|

Ballistic testing

|

Surface Engineering and Materials Degradation Centre

Our purpose-built Surface Engineering, Corrosion and Degradation Laboratory has a variety of environmental ageing and conditioning equipment, electrochemical coating treatments and anodising facilities, including:

Facilities include:

- The environmental ageing and conditioning equipment includes a salt spray and corrosion cabinet

- Electrochemical coating treatments

- Anodising facilities

- Organic coating technologies

- Fundamental electrochemical testing

- Combined stress testing with thermal exposure and moisture immersion