AVRRC Specialised Test Facilities

The AVRRC employs a very wide range of test facilities to underpin our research activities. These include bespoke human factors tools to measure the performance of people with the enabling technology. We are very careful and mindful to ensure the prospective user has as real as possible experience when interacting with the different solutions we are working on. Whilst some facilities take a range of measurements it is the research that involves human participants that require extremely careful setups to ensure we follow approved ethical protocols etc. Whilst many statisticians routinely remove outliers from their data we are very interested in outliers since these may actually be real and the trigger event for the cause of unanticipated behaviour in complex systems.

AVRRC Airbus A320 Wing

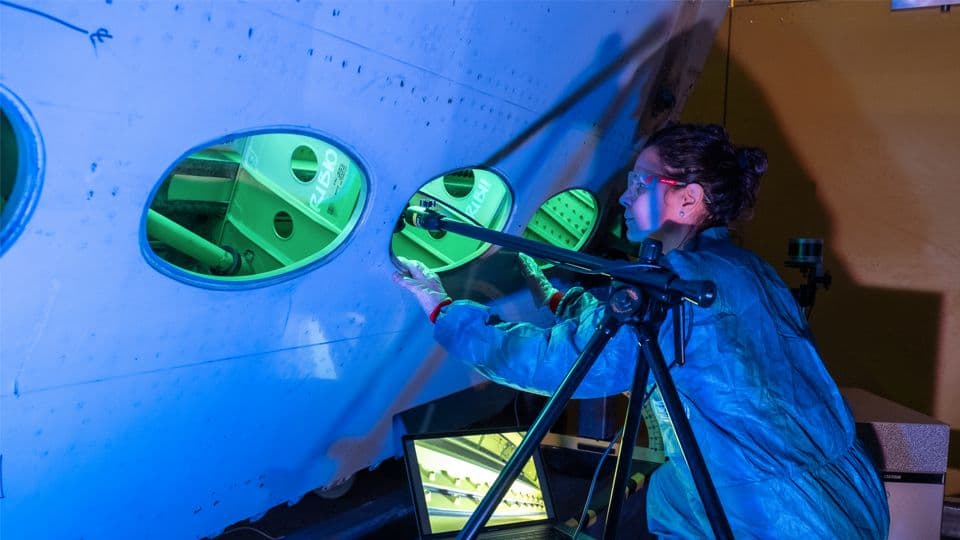

Use of Microsoft HoloLens XR display to track/label regions of interest

The AVRRC undertakes a range of research activities ranging from visual inspection to identification of defects and other issues during wing manufacture and in-service. To support this research the AVRRC have obtained a section of A320 Wing taken from a retired operational aircraft. This provides us with a representative real-world example of an actual wing. Research includes the use of AI and other visual inspection techniques to test the effectiveness of these techniques against more traditional human based inspection.

LU Section of A320 Wing undergoing visual inspection

The AVRRC have been developing techniques to capture image training data sets for training of an AI (machine learning) system. The image shows someone using a HoloLens 2 to track specific regions of interest in the wing.

AVRRC AI for Industrial Inspection

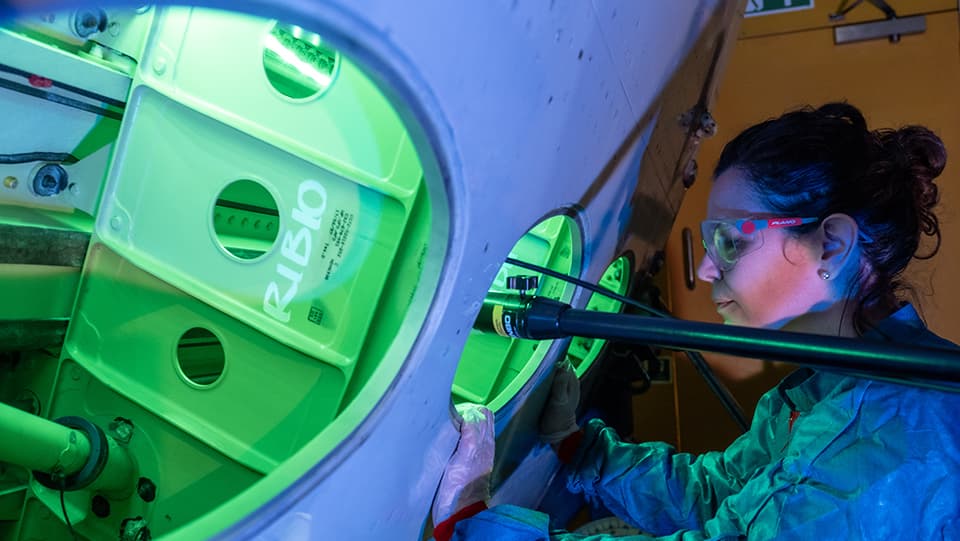

Configuring Image capture for NVIDIA DGX Station AI Machine Learning System

AI Based Manufacturing Anomaly Inspection

Detailed inspection of large, manufactured components such as aircraft wings and other complex structures is necessarily a highly intensive manual process requiring careful inspection, checking for missing or misaligned components, out of tolerance sub-components, surface defects, damage to paint surface, poor bounding of components, etc. Depending on the inspection requirements this can take a significant time, and, in many cases, there cannot be any margin for error.

AVRRC are developing several automated visual inspection systems ranging from AI (machine learning) to more conventional image-based inspection techniques.

However, one of the major challenges with any Machine Learning solution is the requirement for vast amounts of training data. This can be difficult if there are very few (if there are any manufacturing defects). Also, it is not possible to use the many libraries of labelled images in the public domain since these are not representative and in any case care has to be taken when using open-source AI tools because of commercially sensitive requirements. The AVRRC have been investigating the use of multi-modal sensory solutions in conjunction with AI (Machine Learning) to determine whether an AI system can be trained to recognise defects of various kinds. This research has spanned traditional and novel imaging systems along with new AI training methods to see if it is possible to replace/augment the human inspection process.

The image above illustrates a typical automated AI inspection process used in the AVRRC. This has involved the use of an Nvidia DXG Station along with edge computing solutions to act as inference engines. Furthermore, to reduce the requirements for massive test data sets based on real defects novel techniques have been investigated such as generating virtual or synthetic images of possible defects and using these as part of the training activity. Results are extremely promising but remain commercially sensitive. Further research is underway to build on the automated inspection technique with additional focus on different machine learning algorithms.

Non-AI Based Manufacturing Anomaly Inspection

Other non-AI based visual inspection solutions have been shown to work in certain circumstances. The example shown here is where a reference image of a good component can be used with image processing to show various manufacturing anomalies. The novelty here is that the camera alignment does not need to be in the precise position/orientation of the camera used to take the reference image. This technique can be extremely fast and can operate in real-time.

AVRRC Human in the Loop Simulators

The cockpit provides a fully reconfigurable interactive user interface

Fixed Wing Cockpit Simulator

The AVRRC research flight simulator lab has 2 pilot stations (based on a donated Typhoon cockpit from BAE Systems) powered by identical off-the-shelf liquid-cooled PCs. It has three 27” (1920x1080) LCD screens in landscape mode.

These form a single large display area of (bezel-corrected) 6160x1080 pixels through NVIDIA Surround graphics drivers. A single 22" (1920x1080) LCD touchscreen provides flight (instrument) displays.

AVRRC Advanced Cockpit Facility

Flight controls are passive A-10C centre stick and dual throttle replica and there's also a force pressure induced sidestick available. Rudder controls are passive, spring adjustable with toe brakes. Infrared head-tracker and web camera measure pilot head position/orientation.

AVRRC Advanced Cockpit Experimenter's Control Station

UAV Ground Control Station

Using an eye tracker to assess remote UAV operator workload

The AVRRC have piloted several investigations looking at how to reduce multi-crew workload so that a single person (or a maximum of two) can control a remotely operated drone. An advanced ASL eye tracker was used to accurately determine where the ‘remote pilot’s eye was attending to key information and context. This information was used to help develop a suite of display modes and information overlays to support various mission requirements.

The research involved determining mental and cognitive workload under varying levels of stress. A representative set of scenarios were used to test the operator’s decision-making processes. A flight datalogger was developed to capture every pilot action/reaction including time synchronised eye tracking so that we knew exactly what the pilot was looking at. The AVRRC hosts a very capable ground control station that can be configured to suit airborne, ground, sea and space based autonomous and telepresence applications. Due to the highly sensitive/classified nature of the associated research details provided only on request.

Facility configured as a Remote Control Station for UAV

AVRRC Helicopter Cockpit Simulator

4m Vision dome used as helicopter simulator

The AVRRC have researched the development of advanced information displays for helicopter missions. These missions included flying during the day, night and conditions of zero visibility – whilst flying at 50ft above the terrain. This involved simulating an advanced helicopter avionics system with a view to providing time critical information display via head mounted (augmenting reality) displays. In its current configuration the 4m Vision Dome houses a fixed based helicopter flight simulator. The outside world visuals are extremely impressive simulating day, night and poor visibility conditions. Below the pilot's seat is a representative control feel system that can be adjusted to suit different helicopter control configurations. The simulator can be networked to other flight simulators in the AVRRC. Importantly, AVVRC developed augmented display information was flight tested in a real helicopter at Middle Wallop in the conditions mentioned.