Student Portal

Teaching Facilities

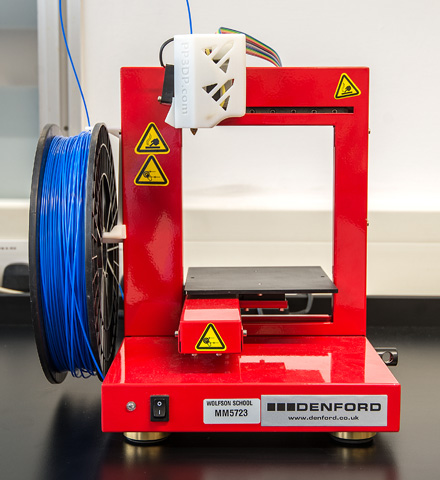

The teaching lab is located in room in the “Department of Mechanical and Manufacturing Engineering”. It has been recently refurbished to comply to the newest standards of interactivity. The teaching lab contains ten Up! 3D Printers (Denford Limited) with are connected to ten computers. The software used is Magics provided by Materialise which enables an easy conversion of CAD files into STL files needed for 3D printing → Info about AM.

In the teaching lab students learn about 3D printing in a hands-on experience. Students can also use the Up! 3D printer to build their own projects which will be presented at the end of the term.

The Up! 3D Printer is a material extrusion based AM process that manufactures components out of either ABS or PLA . The machine uses a heated extrusion nozzle to extrude polymer filament onto a heated build platform in a layer-by-layer fashion. The machine platform can move along the x-axis and can be raised or lower in the z-axis. The extruder head and nozzle can move in the y-axis. The maximum build volume of 140x140x135 mm and a minimum layer thickness of 0.15 mm.