The UK food manufacturing industry is the largest manufacturing sector in the country, contributing more than £28.2bn to the economy.

However, experts studying this area say taking advantage of digital technologies is “vital to the prosperity of the UK food industry” and requires immediate action.

Academics from Loughborough University’s Centre for Sustainable Manufacturing and Recycling Technologies (SMART) together with the Internet of Food Things (IoFT) – a national initiative funded by Engineering and Physical Sciences Research Council (EPSRC) and led by the University of Lincoln – have prepared a report for industry stakeholders that identifies the next steps for the uptake of digital technologies across the food manufacturing supply chain and examines current business successes.

It builds on evidence gathered at an event led by the Centre of SMART and IoFT, which brought together 50 industrial leaders, professional bodies, government representatives and academics to discuss improving productivity in food manufacturing and was hosted at the Loughborough University London campus earlier this year.

The 15-page briefing document is aimed at business leaders and policymakers interested in the cutting-edge ideas for increasing productivity through digitalisation.

It is hoped it will “accelerate the large-scale adoption of digital technologies to improve productivity, in particular by food SMEs (small and medium-sized enterprises)”.

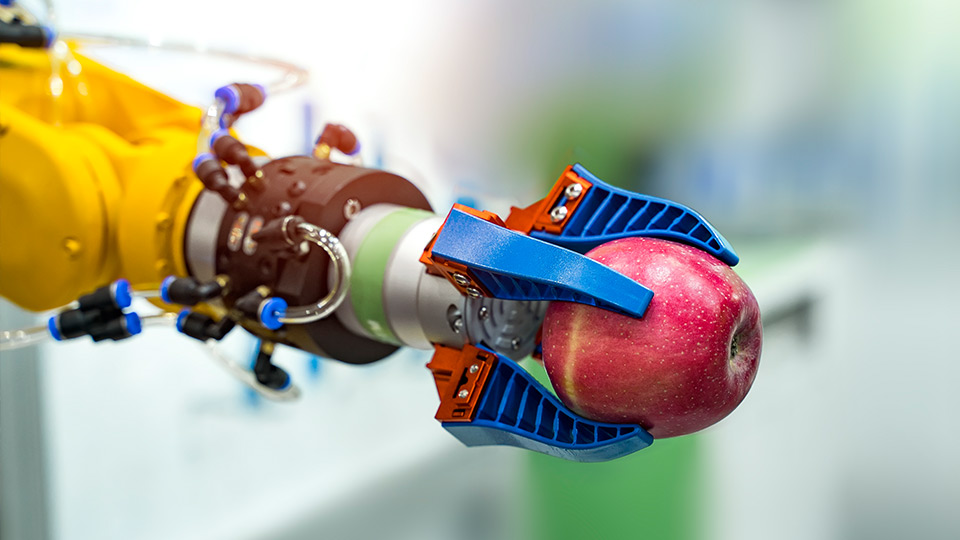

Taking advantage of digital technologies is “vital to the prosperity of the UK food industry”. Image courtesy of Getty Images.

What’s in the briefing document?

Three different ‘digital food’ strands are examined in the brief: real-time resource-efficient production, a resilient and productive food supply chain, and digital technologies to improve consumer engagement.

The sub-sections examine how the adoption of digital technology can impact a wide range of areas such as resource efficiency, food waste reduction, return on investment, and future consumer-driven business models.

A number of case studies are referenced in the report as examples of how technology is already being used to benefit companies in the sector.

Edeka’s digitalised meat processing plant and Barfoot’s asparagus tracking methods are discussed, as are the new emerging food supply chain actors such as Gousto – one of the UK’s leading recipe kit providers.

The briefing document concludes by outlining the current challenges presented by digital technologies and suggests nine ‘next steps’ for the industry.

The recommendations include:

- Generate peer benchmarking information and knowledge on increasing productivity, reducing resource consumption and waste generation through the adoption of digital technologies

- Establish cross-sector partnerships for knowledge sharing on best practices to harness the potential of big data analytics for process optimisation and new food product development

- Increase opportunities for training and education not only for the development of new technology, but in enabling the current workforce to use digital tools

- Create new food safety, quality and traceability standards based on the capabilities of new digital technologies

- Develop user-friendly cost-effective digital tools to support much needed behavioural change to improve sustainable food consumption.

It is hoped the document will “accelerate the large-scale adoption of digital technologies to improve productivity". Image courtesy of Getty Images.

Professor Shahin Rahimifard, Director of the Centre for SMART, said of the briefing document: “Actors across the food manufacturing supply chain are evolving their practices to reduce waste, meet the food security challenge and address changing consumer needs, aided by the emerging technologies of the Fourth Industrial Revolution (Industry 4.0).

“The specific actions proposed by this briefing document aim to remove the existing obstacles for taking full advantage of modern digital technologies within the UK food manufacturing.”

Steve Brewer, IoFT Network Co-ordinator, added: “The elusive goal of greater productivity can be found in a number of pioneering innovations in the food sector, these now need to be scaled up in order to reap the full potential of digitalisation.

“We hope that this report can prepare a pathway for successful digitalisation in the food sector.”

The full ‘Digital Food Briefing Document: digital technologies for improving productivity in food manufacturing’, can be downloaded via the Centre for SMART webpage here.

It can also be found on the IoFT website here.