Oil leakage and power loss from radial shaft seals used in automotive power transmission systems

With the increased demand on downsizing powertrain systems for better energy efficiency, the associated sealing systems are subject to harsher operating conditions, resulting in increased oil leakage rates causing adverse environmental impact and pollution.

Our aim

Radial shaft seals are frequently used in power transmission systems to prevent oil leakage. The importance of these components for operational reliability provides a great challenge for the industry.

Oil leakage from power transmission systems harms the environment and affects product quality and customer satisfaction. Pertinent design and standardising key surface parameters such as surface texture and machine lead angle or shaft lead are paramount.

The former is an inherent property of any surface, which is also commonly referred to as surface roughness, whilst the latter is formed during the manufacture of the shafts. The often contradictory objectives of efficiency, effective sealing and reliability require a combined numerical and experimental approach. A numerical model will be created for surface interactions and hydrodynamic flow in the mixed lubrication regime.

The numerical model will be used to understand the underlying physics and inform design. In parallel, a component-level test rig is created to experimentally validate the numerical model and to benchmark new component designs. Additionally, new standards will be created to characterise the waviness and roughness of the contact surfaces measured using optical interferometers.

Our research

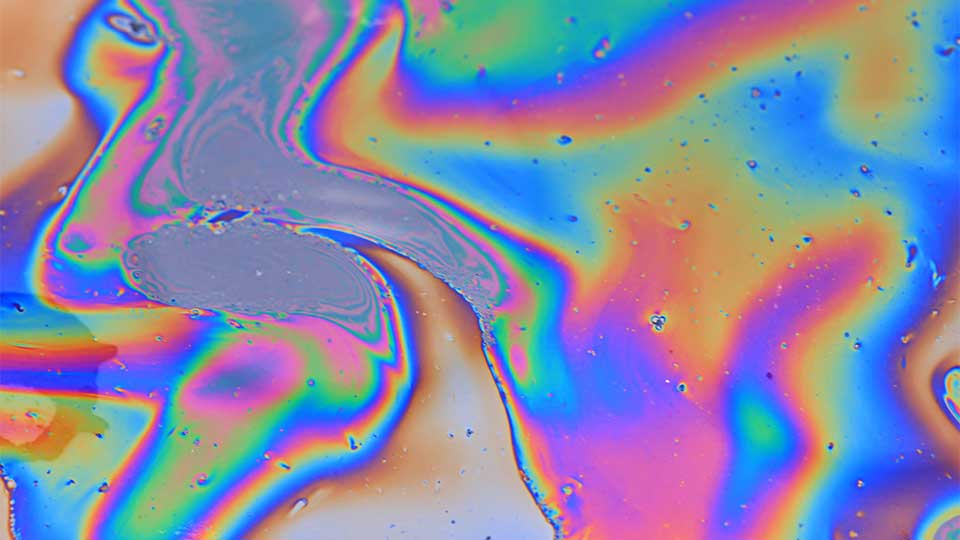

The research uses extensive metrology equipment such as optical microscopy, and white light interferometry to assess the surface topography of the sealing pairs. The research also involves using sensors to monitor the vehicle's performance and the developed test rigs under this programme. Computational models are also designed for an in-depth understanding of the details of the leakage mechanism.

Our outcomes

The research has highlighted the impact that the utilised manufacturing methods in industry can have on the radial lip seal performance. It is shown that specific machining methods used in manufacturing can influence the leakage rate and power loss from radial lip seal conjunctions.

Project lead: Ramin Rahmani

This is an international collaborative research focused on combined experimental and computational analysis of the leakage from radial lip seals, used extensively in many industrial applications, particularly in the transport sector. The subsequent optimisation of such systems will allow for the design of sealing systems which result in minimal adverse environmental impact through superior performance.