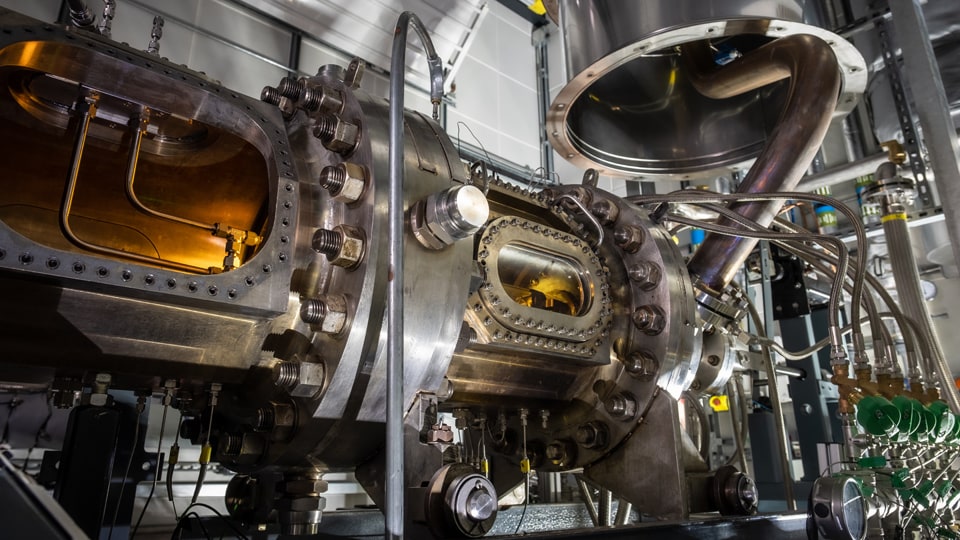

Our facilities

Our world-class state of the art facilities to turn breakthrough ideas into practical solutions.

NCCAT supports a range of low/mid TRL activities crucial to the development of future gas turbine combustion systems whilst also supporting the development of technologies in other aerothermal and combustion related areas.

Examples of facilities include:

- A modern 850m2 purpose-built laboratory incorporating 8 test cells.

- Specialist plant infrastructure and bespoke instrumentation and control systems to support single-phase and two-phase, non-reacting and reacting experiments at various flow rates (steady state and transients) over a wide range of pressure and temperature conditions:

- Sub-atmospheric (down to 240K, 0.3bara),

- Near atmospheric (288K, 1bara),

- Elevated pressures and temperatures (up to 900K, 10bara).

- Liquid and gaseous fuel types including Jet A1, Sustainable Aviation Fuels (SAFs) and hydrogen

- Aerodynamic open area measurement of test components and assemblies

- Heat transfer and cooling performance determination under convective and radiative heat loads

- Access to a wide range of established and modern instrumentation:

- Standard aerothermal measurement techniques (e.g. miniature five-hole probes, hot-wire anemometry, scalar mixing and high temperature aerothermal acoustic pressure capturing systems

- Advanced laser diagnostics (e.g. particle image velocimetry, planar laser induced fluorescence, emission reabsorption laser induced fluorescence, particle doppler anemometry, pressure sensitive paint, thermographic liquid crystals)

- An extensive range of optical imaging techniques to evaluate non-reacting and reacting flow field characteristics

- Techniques for rapid evaluation of fuel injector characteristics including effective area, flow number, cone angle and patternation

- The latest reacting flow diagnostic techniques for quantification of gaseous and soot emissions by various metrics

- A range of industry-standard instruments for the measurement of chemical and mechanical properties of liquid fuels

- Access to a wide range of established and modern instrumentation:

- A 100m2 workshop comprising a range of modern manual and CNC machine tools

The NCCAT activities undertaken also involve Reacting and non-reacting, single and two-phase numerical modelling (1D network, CFD and machine learning) of various combustion processes, heat transfer and combustor related phenomena.

We welcome enquiries from prospective clients about NCCAT's capabilities, please get in touch.