With the global space industry booming—valued at £17.5 billion in the UK alone—the demand for efficient, scalable solar power is rapidly growing.

The European Space Agency predicts a leap from just 1 MWp/year to 10 GWp/year of space solar demand by 2035, driven by expansion of satellite constellations like SpaceX’s Starlink and the rise of space-based manufacturing, including semiconductors and fiber optics.

Currently, space missions rely on either silicon or multi-junction solar cells (MJSCs), with MJSCs dominating due to their high efficiency, but their complex manufacturing and high costs limit scalability.

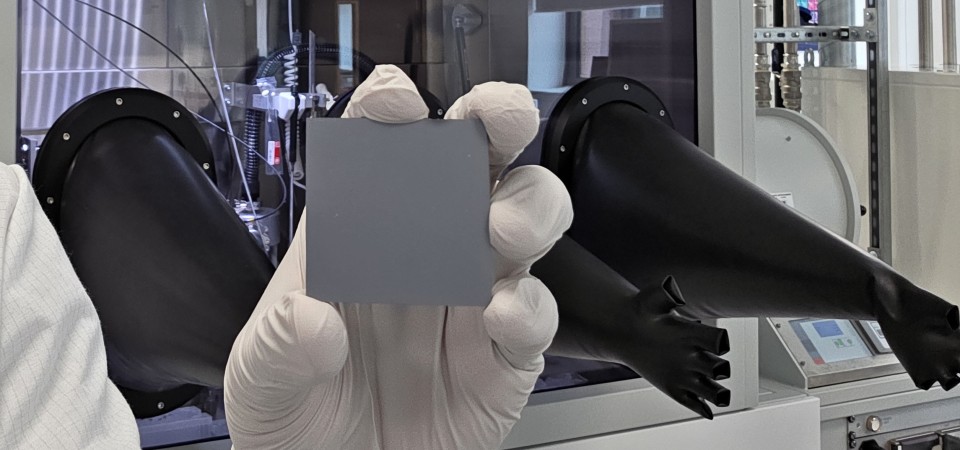

The new CdTe-on-glass technology, first tested in space aboard the AlSat-Nano CubeSat, offers a lighter, cheaper, and highly radiation-resistant alternative, targeting 20% efficiency in space and already achieving 23.1% on Earth.

The new three-year collaboration is supported by UKRI EPSRC funding and leverages world-class facilities at both universities.

Swansea’s Centre for Integrative Semiconductor Materials (CISM) houses advanced tools like the AIXTRON CCS MOCVD system, while Loughborough contributes its National Facility for High-Resolution Cathodoluminescence Analysis, essential for studying solar and optoelectronic devices.

Commenting on the collaboration, Michael Walls, Professor of Photovoltaics in Loughborough’s Centre for Renewable Energy Systems Technology (CREST) said "Space technology is an exciting growth industry. Reducing the weight of the payload is critical to reduce launch costs.

“This project aims to develop a lower weight power source by depositing thin film solar cells directly onto the protective cover glass. The technology will also enable longer deployment in space because thin film cadmium telluride solar cells are exceptionally radiation-hard.”

Professor Paul Meredith, Director of CISM at Swansea University said: “CISM has previously focused on clean energy, efficient power and microelectronics, semiconductors in healthcare, and over-the-horizon semiconductors, but more recently it has been expanding into the development of semiconductor technology for space applications through our UK-first Space Semi-Tech Foundry programme.

“This latest partnership is an example of this as it addresses a critical need and a unique opportunity to support the UK’s strategic vision to capture a significant share of the global space technology market.

“Our technology offers higher specific power, longer service life in space, and significantly lower costs—key advantages for powering the next generation of space missions.”

The project also benefits from strong industry backing, with six partners contributing technical expertise and in-kind support valued at £112,000. The partners are: 5N Plus Inc. (Canada); AIXTRON (UK); CTF Solar GmbH (Germany); Teledyne Qioptiq (UK); Manufacturing Technology Centre (UK), and Satellite Applications.

ENDS

Picture: Highly uniform CdTe photovoltaic material deposited by close-coupled showerhead MOCVD