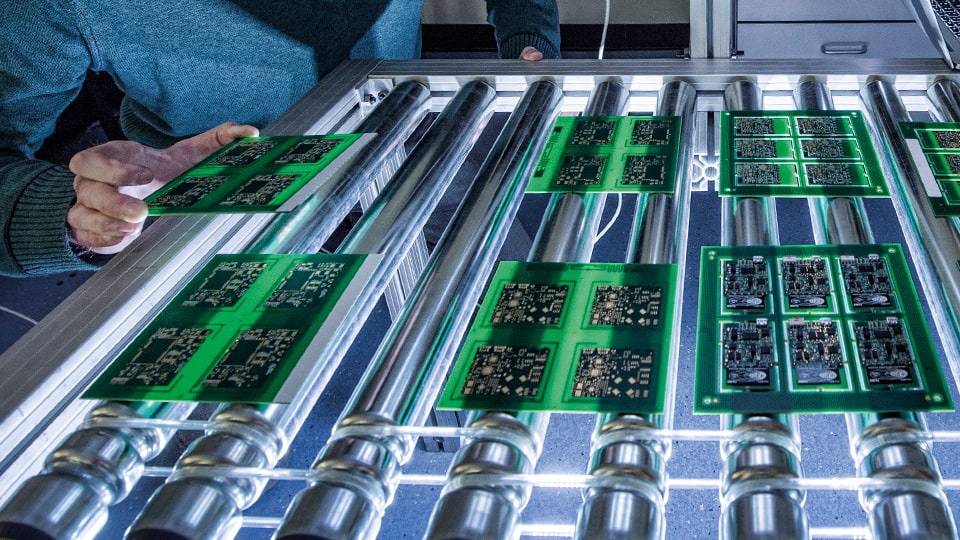

High value manufacturing

Manufacturing has been an integral part of Loughborough University since it was founded in 1909 as a Technical Institute with an Instructional Factory. Today our focus on manufacturing has never been stronger.

We are applying fundamental science to create and develop cutting edge, next generation manufacturing processes and technologies. We are focused on creating enhanced capabilities, productivity and quality, whilst prioritising resilience and sustainability.

Loughborough is leading research into some of society’s biggest cross-sector and interdisciplinary challenges, including the future of Smart Manufacturing and the necessary shift towards a more Circular Economy. Our many strengths include collaborative robotics and intelligent autonomous systems, and sustainable manufacturing.